Ferry Cap Screws

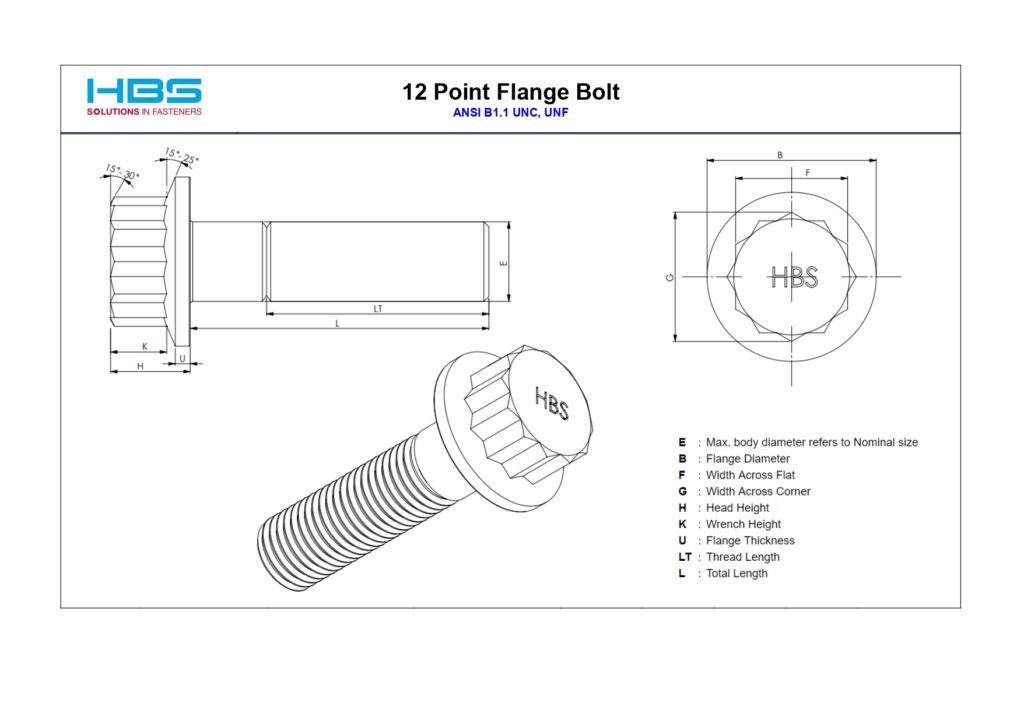

Technical Specification:

- 12-Point Cap Screws

- Ferry Cap Screws

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Exploring Precision and Performance: The 12-Point Screw

In the intricate world of fasteners, where precision is paramount and performance is prized, the 12-point screw stands out as a symbol of ingenuity and reliability. Let’s delve into the features, advantages, and applications of the 12-point screw, unlocking its potential for a wide range of engineering and construction projects.

Understanding the 12-Point Screw:

Unlike traditional screws with a single slot or hexagonal head, the 12-point screw boasts a unique design featuring twelve recessed points arranged in a circular pattern around the head. This innovative configuration provides multiple points of contact with a compatible wrench or socket, offering enhanced grip and torque transmission for secure and efficient fastening.Key Features and Advantages:

- Enhanced Torque Transmission: The 12-point design of the screw head allows for increased torque transmission compared to standard screws, enabling more efficient and precise tightening of fasteners.

- Reduced Risk of Stripping: With twelve recessed points of contact, the 12-point screw distributes torque evenly, reducing the risk of stripping or rounding of the screw head during tightening or loosening operations.

- Improved Accessibility: The multiple points of contact on the screw head provide greater accessibility in tight or hard-to-reach spaces, allowing for easier installation and removal in challenging environments.

- High-Strength Materials: Manufactured from high-grade materials such as stainless steel or alloy steel, 12-point screws offer exceptional strength, durability, and corrosion resistance, making them suitable for demanding applications.

Applications of 12-Point Screws:

12-point screws find use in a wide range of industries and applications, including:- Automotive Engineering: Used in engine assembly, transmission systems, and chassis components where high torque and reliability are essential.

- Aerospace Manufacturing: Employed in aircraft assembly and maintenance for critical fastening applications requiring precision and durability.

- Heavy Machinery: Utilized in construction equipment, mining machinery, and industrial machinery for securing structural components and critical assemblies.

- High-Performance Racing: Trusted by professional racing teams for securing engine components, suspension systems, and chassis components in high-speed vehicles.