Our Products

Explore our Stud Bolts

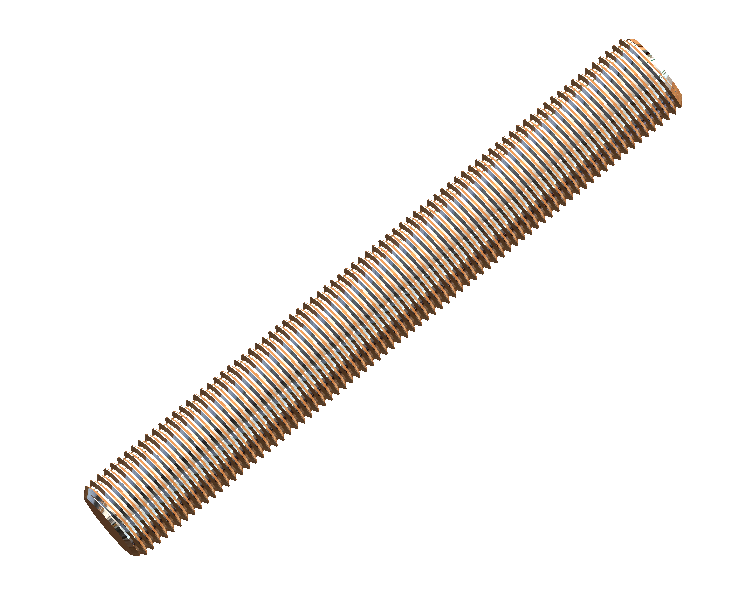

Unlocking the Potential of Stud Bolts: A Comprehensive Guide

Stud Bolts, often regarded as the unsung heroes of the fastening world, play a crucial role in providing secure and reliable connections across a myriad of industries. Whether in construction, manufacturing, or engineering, these specialized fasteners offer unique advantages that make them indispensable for various applications.

Understanding Stud Bolts:

Stud Bolts differ from traditional bolts in that they lack heads; instead, they feature threads on both ends, allowing them to be screwed into a tapped hole and secured with nuts on either side. This design enables them to create a strong and stable connection between two components without the need for a wrench or socket on one end.Features and Benefits:

- Versatility: Stud Bolts are highly versatile, capable of accommodating a wide range of applications. From structural connections to machinery assembly, they offer flexibility and adaptability in diverse environments.

- Ease of Installation: The threaded design of Stud Bolts simplifies installation, particularly in scenarios where access is limited or when working with large or cumbersome components. This ease of installation translates to time and cost savings during assembly and maintenance tasks.

- Secure Fastening: By utilizing nuts on both ends, Stud Bolts provide a secure and stable connection that minimizes the risk of loosening or failure, even under high levels of vibration or stress. This makes them ideal for critical applications where safety and reliability are paramount.

Applications of Stud Bolts:

Stud Bolts find extensive use across various industries and applications, including:- Piping Systems: Stud Bolts are commonly used to secure flanges in piping systems, ensuring leak-free connections and preventing joint separation.

- Structural Steelwork: In construction projects, Stud Bolts play a vital role in securing structural components such as beams, columns, and trusses, providing stability and load-bearing capacity.

- Machinery Assembly: Stud Bolts are employed in the assembly of machinery and equipment, facilitating the joining of components and ensuring operational integrity.

Conclusion:

Stud Bolts epitomize the fusion of simplicity and effectiveness in the realm of fastening solutions. Their unique design, coupled with their versatility and reliability, makes them indispensable for a wide range of applications across various industries.Whether you’re constructing a building, assembling machinery, or performing routine maintenance, Stud Bolts offer a dependable and efficient means of creating strong and secure connections. With their ability to withstand the rigors of demanding environments, Stud Bolts stand as a testament to the enduring importance of quality fasteners in modern engineering and construction.