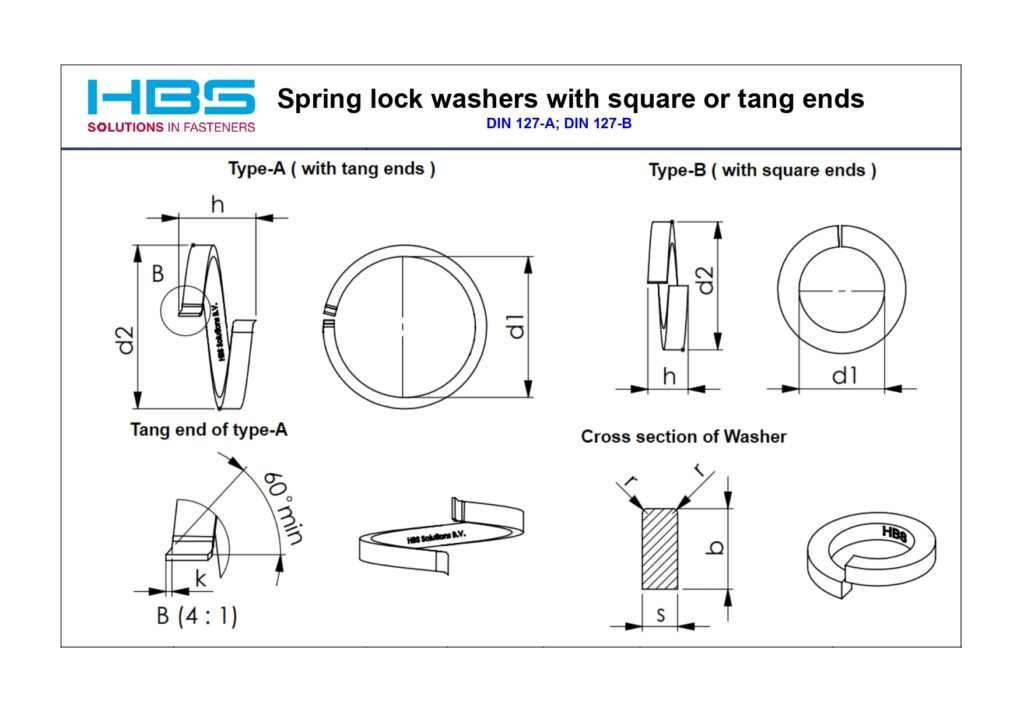

DIN 127

Spring Lock Washer Form-A

Spring Lock Washer Form-A/B

Technical Specification:

- Spring Lock Washer

- DIN 127

- Diameter: Metric or Inch

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Unlocking Fastener Stability: DIN 127 Spring Lock Washer vs. DIN 125 Plain Washer

In the realm of fasteners, the choice between DIN 127 Spring Lock Washer and DIN 125 Plain Washer can significantly impact the stability and reliability of connections. While both serve essential functions in distributing loads and protecting surfaces, there are distinct scenarios where DIN 127 Spring Lock Washer outshines its counterpart. Let’s explore why, in some cases, DIN 127 proves superior to DIN 125, offering enhanced fastener stability and peace of mind.

Dynamic Environments Demand Dynamic Solutions:

- Vibration Resistance: DIN 127 Spring Lock Washer’s unique helical design enables it to exert radial force when compressed, effectively resisting loosening caused by vibration or dynamic loads. In applications where machinery or equipment undergoes frequent vibrations, such as automotive assemblies or industrial machinery, DIN 127 ensures continuous tension on the fastener, maintaining stability over time.

- Preload Maintenance: Unlike DIN 125 Plain Washer, which relies solely on friction to secure the fastener, DIN 127 actively maintains preload by exerting spring-like pressure on the bolt or nut. This feature is particularly beneficial in critical applications where maintaining consistent clamping force is essential for structural integrity, such as construction, aerospace, or power generation.

Versatility Meets Precision:

- Adaptability to Varied Surfaces: DIN 127 Spring Lock Washer’s spring-like action allows it to adapt to irregularities in mating surfaces, ensuring uniform contact and load distribution. This adaptability is especially advantageous in assemblies with imperfect or uneven surfaces, where DIN 127 provides a reliable and stable connection, whereas DIN 125 may not conform as effectively.

- High-Stress Environments: In environments subject to thermal expansion, cyclic loading, or fluctuating temperatures, DIN 127 Spring Lock Washer excels in maintaining fastener stability. Its ability to withstand varying conditions without compromising tension makes it a preferred choice in high-stress applications, offering enhanced reliability and longevity compared to DIN 125.