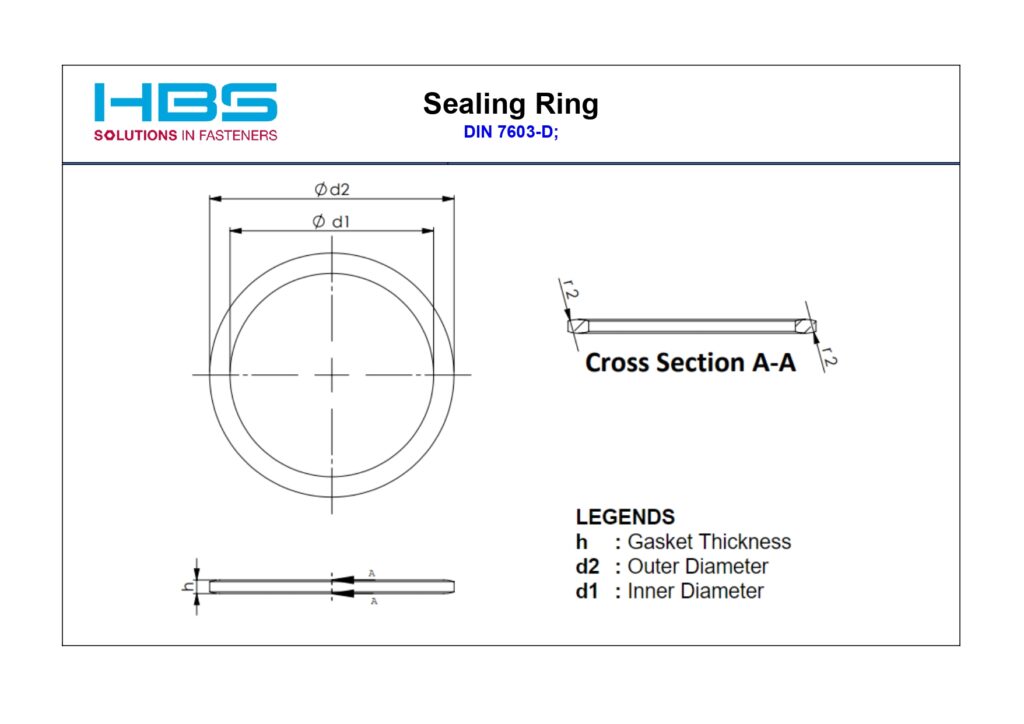

Sealing Ring Form-D

Technical Specification:

- Sealing Ring Form-D

- DIN 7603-D

- Diameter: Metric or Inch

Possible materials:

- ISO: St 4.8/ 5.6 / 8/ 10/ 10.9/ 12/ 12.9

- ISO: A2,A4, 304L, 316L

- ANSI/ASME: A/SA193-B7/ B7M/ L7/ L7M/ B8/ B8M

- ANSI/ASME: A/SA194 2H/ Gr.8/ Gr.8M

- Alloy: Monel-400, Alloy-201, Inconel-625

- Non-Alloy: CS, Soft Iron, Armco, Titanium, Graphite, Non-Asbestos

- DIN Werkstoff: 25CrMo4, 42CrMo4 , X5CrNiMo17-12-2, X5CrNi 18-10, X36CrMo17

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Elevating Sealing Precision: DIN 7603D Sealing Washers/Gasket

In the realm of precision engineering, where every seal must withstand the test of time and pressure, DIN 7603D sealing washers/gasket emerge as indispensable components, offering enhanced performance and reliability over their counterparts. Specifically designed to meet the demands of rigorous applications, DIN 7603D sealing washers/gasket provide a superior sealing solution compared to DIN 7603A washers. Let’s delve into the reasons why DIN 7603D is required over DIN 7603A, highlighting the distinctive features and benefits that set it apart.

Redefining Precision:

DIN 7603D sealing washers/gasket represent a refinement in sealing technology, meticulously engineered to meet exacting standards and surpass the performance of traditional sealing washers. With their precise dimensions, optimal material composition, and advanced manufacturing processes, DIN 7603D washers/gasket offer unparalleled sealing precision in critical applications.

Enhanced Durability:

One of the key reasons for preferring DIN 7603D over DIN 7603A is its enhanced durability and resilience. DIN 7603D sealing washers/gasket are crafted from premium-grade materials with superior resistance to corrosion, abrasion, and chemical degradation. This ensures longevity and reliability in harsh operating environments, where conventional washers may degrade prematurely.

Optimized Sealing Performance:

DIN 7603D sealing washers/gasket are designed to deliver superior sealing performance, even under extreme conditions of temperature, pressure, and vibration. Their precise geometry and uniform compression ensure a tight and consistent seal, minimizing the risk of leaks and maintaining system integrity over prolonged periods of operation.

Broad Compatibility:

While DIN 7603A washers offer reliable sealing in standard applications, DIN 7603D washers/gasket are preferred for critical applications where enhanced performance and compatibility are essential. DIN 7603D washers/gasket are designed to meet the stringent requirements of high-pressure hydraulic systems, precision machinery, and other demanding applications where reliable sealing is paramount.

Regulatory Compliance:

In industries governed by stringent regulations and standards, such as aerospace, automotive, and manufacturing, DIN 7603D sealing washers/gasket offer compliance with industry-specific requirements and specifications. Their superior performance and reliability make them the preferred choice for critical sealing applications, ensuring compliance with regulatory standards and quality assurance protocols.