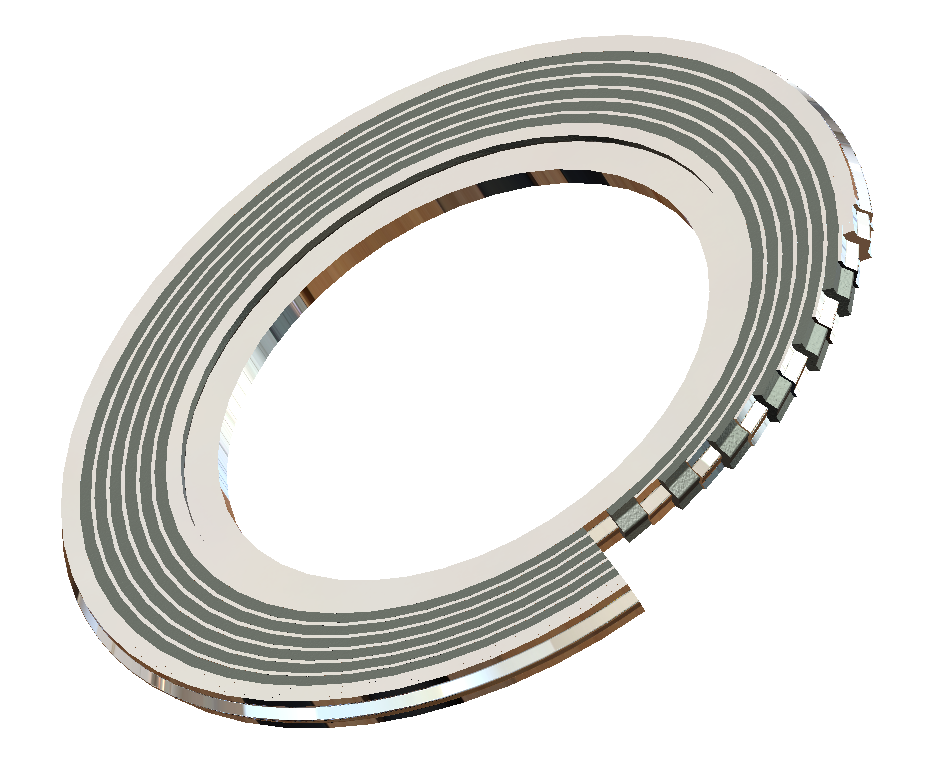

Spiral Wound Gaskets

Technical Specific

- Diameter: Metric or Inch

Possible materials:

- ISO: St 4.8/ 5.6 / 8/ 10/ 10.9/ 12/ 12.9

- ISO: A2,A4, 304L, 316L

- ANSI/ASME: A/SA193-B7/ B7M/ L7/ L7M/ B8/ B8M

- ANSI/ASME: A/SA194 2H/ Gr.8/ Gr.8M

- Alloy: Monel-400, Alloy-201, Inconel-625

- Non-Alloy: CS, Soft Iron, Armco, Titanium, Graphite, Non-Asbestos

- DIN Werkstoff: 25CrMo4, 42CrMo4 , X5CrNiMo17-12-2, X5CrNi 18-10, X36CrMo17

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Crafting Sealing Excellence: The Artistry of Spiral Winding Gaskets with Filler

Spiral winding gaskets with filler are one of the masterpieces of engineering ingenuity and artistic craftsmanship. Like skilled artisans, these gaskets blend the meticulous technique of spiral winding with the harmonious addition of filler materials, creating a symphony of sealing excellence that resonates across diverse industries. Let us embark on a journey to unravel the creativity, versatility, and unwavering performance of spiral winding gaskets with filler, where each turn of the spiral unveils a tale of precision and perfection.

A Tapestry of Technique:

Spiral winding gaskets with filler weave a tapestry of technique, where precision winding and meticulous craftsmanship converge to create a seamless seal. Utilizing advanced manufacturing processes, thin metal strips are precisely wound in a spiral pattern, forming the backbone of the gasket. The interstitial spaces are then filled with carefully selected filler materials, such as flexible graphite, PTFE, or non-asbestos fibers, ensuring a resilient and conformable sealing surface.

Versatility in Composition:

The choice of filler material imbues spiral winding gaskets with unique properties and capabilities tailored to specific applications. Flexible graphite, for example, excels in high-temperature environments, providing excellent thermal stability and chemical resistance. PTFE, renowned for its low friction and non-stick properties, is ideal for applications requiring superior chemical resistance and tight sealing. Non-asbestos fibers offer a cost-effective solution with good mechanical strength and compatibility with a wide range of fluids and gases. Ceramic fibers provide exceptional thermal insulation and resistance to extreme temperatures, making them suitable for demanding applications in industries such as petrochemicals and power generation.

A Symphony of Sealing Excellence:

As the spiral unwinds, a symphony of sealing excellence unfolds, where precision meets performance in perfect harmony. The seamless integration of metal and filler material creates a gasket that is more than just a seal—it’s a testament to creativity, craftsmanship, and unwavering reliability. From flange connections in industrial machinery to critical joints in aerospace applications, spiral winding gaskets with filler orchestrate sealing perfection, ensuring operational integrity and peace of mind.

Unveiling Artistry in Engineering:

In the world of engineering, where functionality often takes precedence, spiral winding gaskets with filler stand as a testament to the artistry that resides within precision manufacturing. Each gasket is a work of art, meticulously crafted to meet exacting standards and surpass performance expectations. Beyond their sealing capabilities, these gaskets exemplify the marriage of creativity and engineering, reminding us that even the most practical solutions can be infused with beauty and elegance.