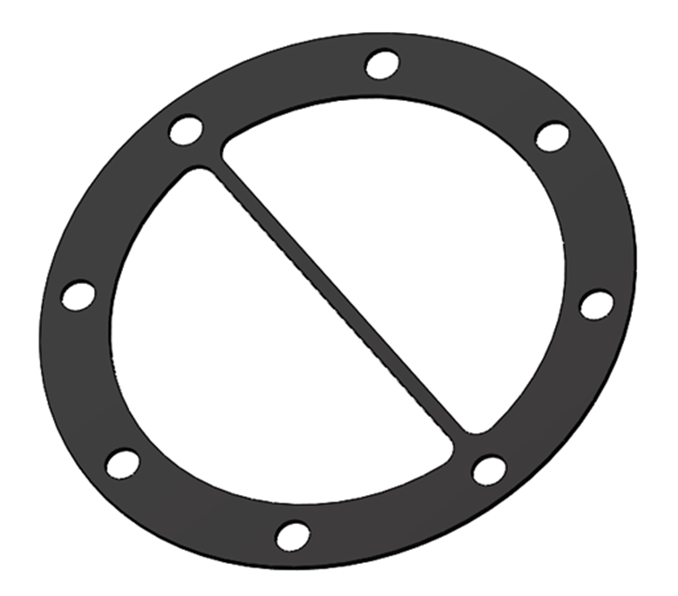

Non-Asbestos Gaskets

Technical Specification:

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Non-Asbestos Gaskets: Redefining Safety and Performance in Sealing Solutions

In the ever-evolving landscape of industrial sealing solutions, non-asbestos gaskets emerge as pioneers of safety, sustainability, and performance. These innovative gaskets, crafted without the use of asbestos fibers, offer a reliable and environmentally conscious alternative for critical sealing applications. Let’s delve into the realm of non-asbestos gaskets, exploring their composition, advantages, and versatile applications where safety and performance are paramount.

Composition and Construction:

Non-asbestos gaskets are meticulously engineered using a combination of synthetic fibers, elastomers, fillers, and binders to achieve optimal sealing performance. While traditional asbestos gaskets posed health risks due to asbestos exposure, non-asbestos gaskets provide a safe and sustainable solution without compromising on performance. The composition of non-asbestos gaskets may vary depending on specific application requirements, but they typically incorporate materials such as aramid fibers, fiberglass, carbon fibers, and elastomeric binders.Advantages of Non-Asbestos Gaskets:

- Safety: Unlike asbestos gaskets, which pose serious health risks due to asbestos exposure, non-asbestos gaskets offer a safe and environmentally friendly sealing solution. By eliminating asbestos fibers from the composition, non-asbestos gaskets ensure the well-being of workers and compliance with health and safety regulations.

- Performance: Non-asbestos gaskets deliver performance on par with or even exceeding that of traditional asbestos gaskets. With advancements in material science and manufacturing techniques, non-asbestos gaskets offer excellent resistance to high temperatures, pressures, and chemical exposures, making them suitable for a wide range of industrial applications.

- Environmental Sustainability: Asbestos-free manufacturing processes reduce environmental impact and contribute to sustainability efforts. Non-asbestos gaskets align with modern environmental regulations and initiatives aimed at minimizing the use of hazardous materials and promoting eco-friendly practices in industrial settings.

- Versatility: Non-asbestos gaskets are available in a variety of configurations, including sheet gaskets, spiral wound gaskets, and cut gaskets, to suit diverse sealing requirements. They find application in industries such as oil and gas, chemical processing, power generation, automotive, and manufacturing, where reliable sealing is essential for operational integrity.

Applications of Non-Asbestos Gaskets:

- Flange Connections: Non-asbestos gaskets are commonly used in flange connections to create leak-free seals between pipes, valves, and other components in piping systems. Their ability to withstand high temperatures and pressures makes them ideal for critical sealing applications in refineries, chemical plants, and power plants.

- Heat Exchangers: Non-asbestos gaskets provide reliable sealing in heat exchangers, where they prevent leakage of fluids and maintain thermal efficiency. Their resistance to thermal cycling and compatibility with various heat transfer fluids make them suitable for use in HVAC systems, industrial boilers, and refrigeration units.

- Pump and Valve Sealing: Non-asbestos gaskets play a crucial role in sealing pumps, valves, and other rotating equipment in industrial processes. They ensure tight seals to prevent leakage of fluids and maintain system efficiency and reliability.

- Automotive Gaskets: Non-asbestos gaskets find application in automotive engines, exhaust systems, and fluid handling systems, where they provide reliable sealing under the demanding conditions of combustion, vibration, and thermal cycling.