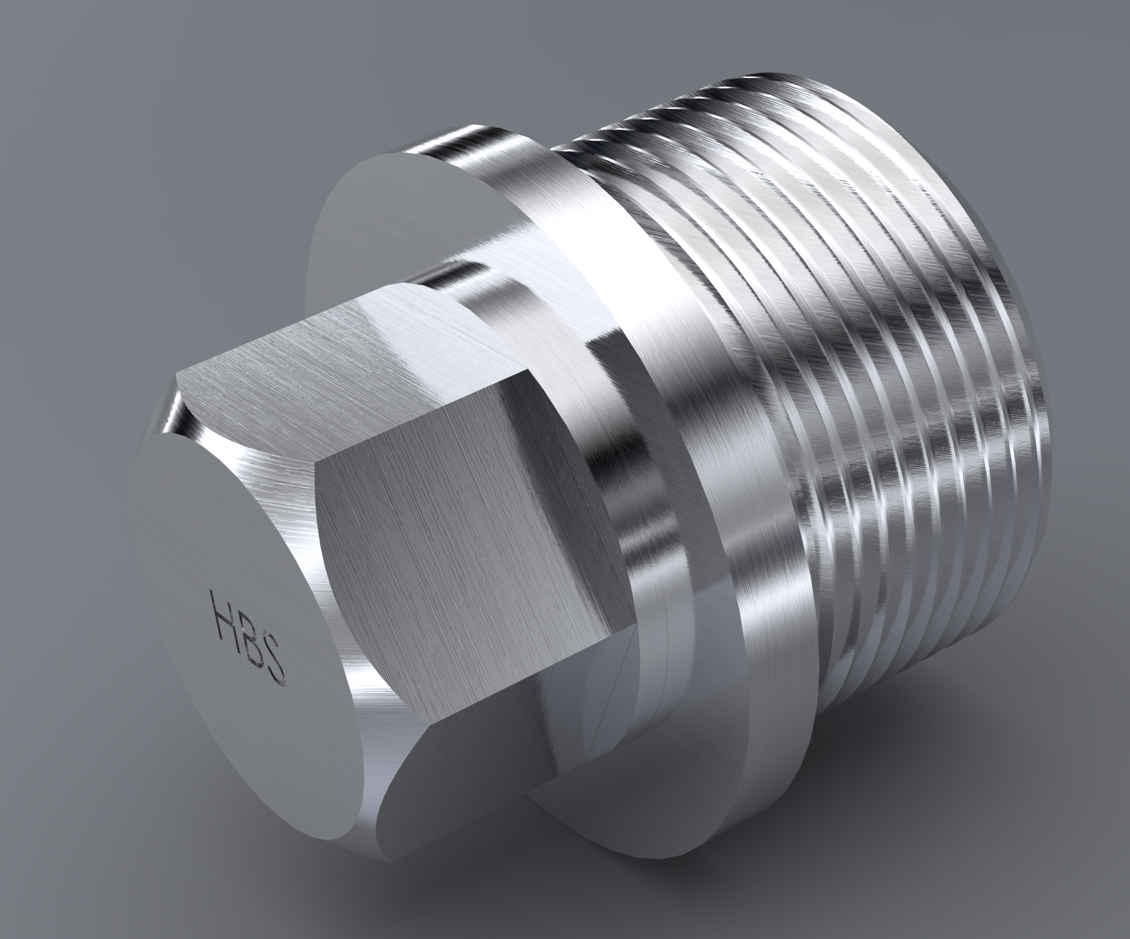

Takecoat-1000: Unrivaled Protection for Extreme Conditions.

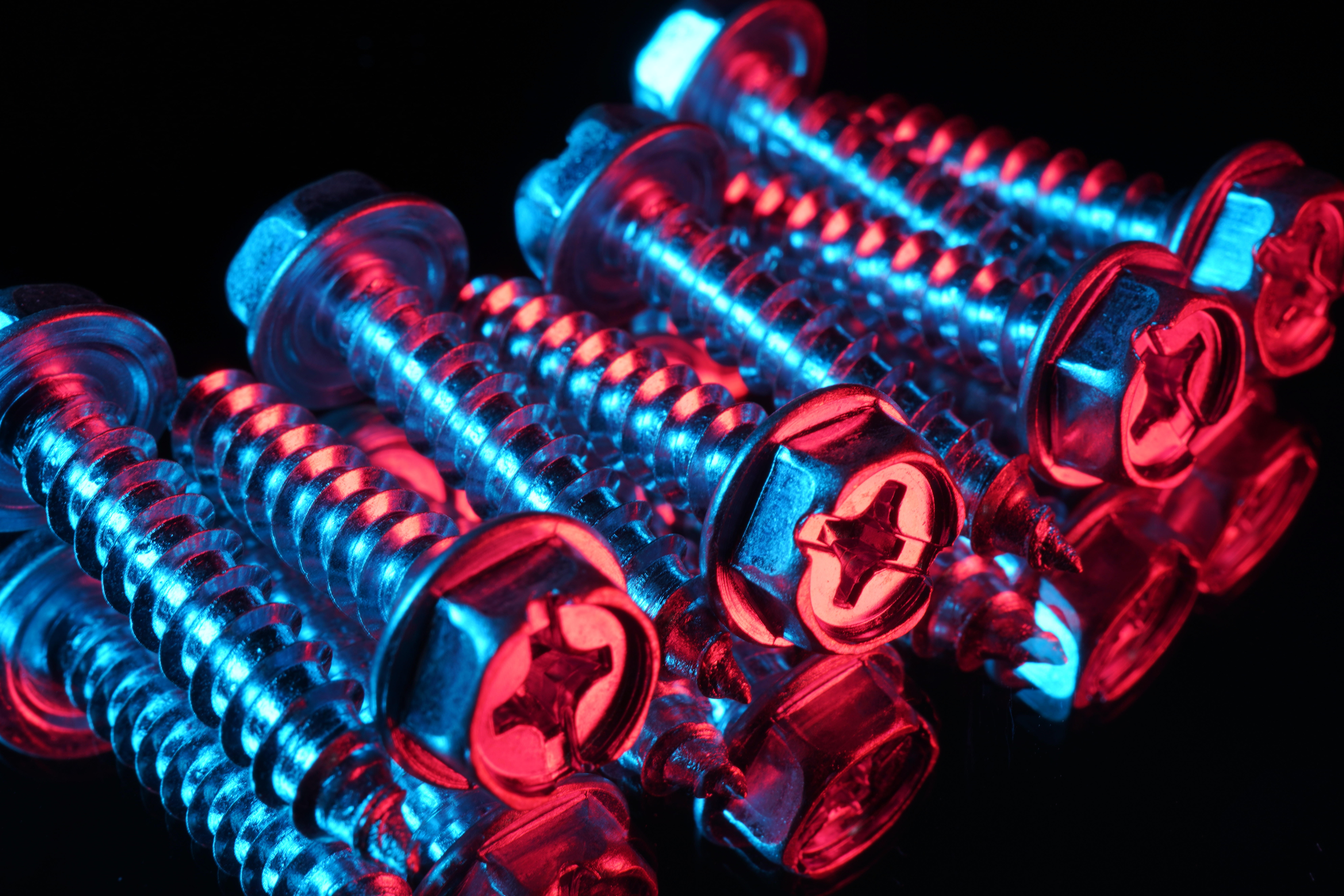

PTFE/Xylan Coating: Exceptional Durability Meets Advanced Lubrication.

Zinc Plated: Combining Strength with Corrosion Resistance for Lasting Performance.

Zinc-Nickel Alloy Coating: Enhanced Durability and Superior Corrosion Protection.

Geomet-500: The Pinnacle of Eco-Friendly, High-Performance Coating Technology.

Sherardizing: The Ultimate Solution for Long-Lasting, Uniform Corrosion Protection.

Hot-Dip Galvanized: Robust and Reliable Coating for Optimal Environmental Resistance.

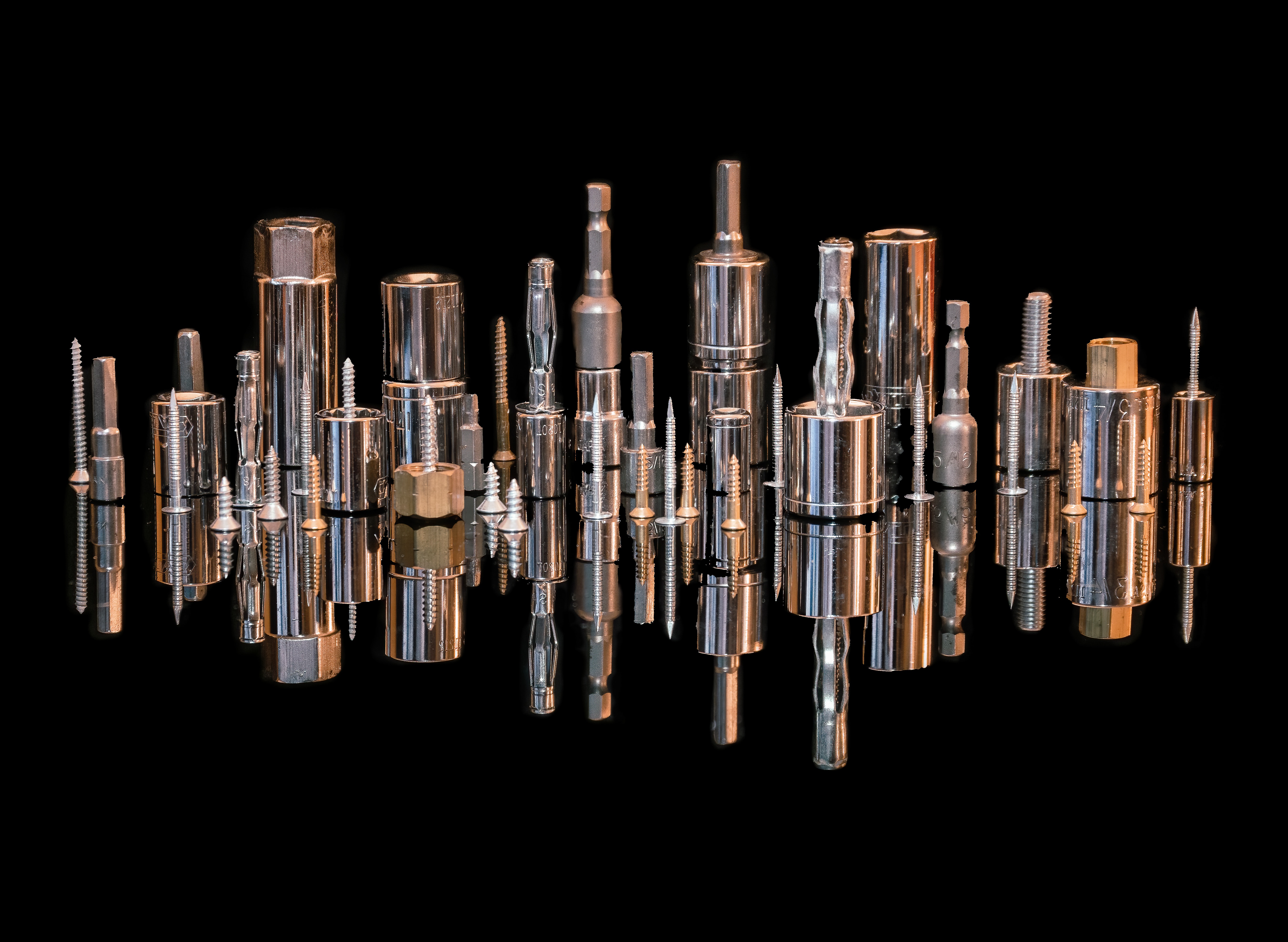

Our Solution includes TAKECOAT-100 PTFE XYLAN Zinc Plated Zinc Nickel GEOMET-500 Hot-Dip Galvanized Sheradizing

TAKECOAT-1000

Takecoat-1000 stands as a testament to advanced coating technology, offering unmatched protection in the most extreme conditions. This innovative coating solution is engineered to provide exceptional resistance to corrosion, abrasion, and high temperatures, making it ideal for use in harsh industrial environments. Its robustness ensures a longer lifespan for fasteners, reducing the need for frequent replacements and maintenance. Whether used in marine, automotive, or heavy machinery applications, Takecoat-1000 provides a shield that not only enhances performance but also preserves the integrity of the components it coats.

PTFE/Xylan/Fluropolymer

The PTFE/Xylan Coating offers a unique combination of durability and advanced lubrication, setting a new standard in surface treatments. This dual-action coating is known for its exceptional non-stick properties and resistance to chemicals, reducing friction and wear on components. Ideal for applications requiring a low coefficient of friction, such as in automotive or aerospace parts, the PTFE/Xylan Coating not only extends the life of fasteners but also ensures their smooth operation in a variety of conditions, making it a go-to solution for high-performance requirements.

Zinc Plated

Zinc plating is a tried and tested solution for adding strength and corrosion resistance to metal components. This coating process not only enhances the durability of fasteners but also provides an extra layer of protection against environmental elements. Ideal for both indoor and outdoor applications, zinc plated coatings are commonly used in construction, automotive, and consumer electronics for their ability to extend the lifespan of parts. The balance between toughness and resistance makes zinc plated fasteners a reliable and cost-effective choice for a wide range of industries.

Zinc-Nickel

The Zinc-Nickel Alloy Coating is engineered for those who demand enhanced durability along with superior corrosion protection. This advanced coating combines the strength of zinc with the resilience of nickel, offering a formidable barrier against rust and wear. Particularly effective in saline or high-temperature environments, Zinc-Nickel coated fasteners are ideal for automotive, aerospace, and marine applications. This coating not only prolongs the life of components but also maintains their performance and appearance in the most challenging conditions.

Geomet-500

Geomet-5000 represents the pinnacle of eco-friendly coating technology, delivering high-performance protection without compromising on environmental safety. This innovative coating is free of hazardous metals and is highly resistant to corrosion, making it ideal for automotive, construction, and renewable energy applications. Its unique water-based formula ensures uniform coverage and excellent adhesion, providing long-lasting protection for fasteners and components. Geomet-5000 is the choice for industries looking to balance ecological responsibility with superior performence.

Hot-Dip Galvanized

The Hot-Dip Galvanized process is a hallmark of reliability, providing a robust and environmentally resistant coating for metal components. This method involves immersing parts in molten zinc, resulting in a thick, protective layer that is exceptionally resistant to corrosion and wear. Widely used in construction, infrastructure, and utility applications, hot-dip galvanized coatings ensure a long service life for steel structures exposed to the elements. Its ability to withstand environmental stressors makes it an ideal choice for projects demanding high durability and low maintenance.

Sherardizing

Sherardizing offers unparalleled uniform corrosion protection, especially for intricate metal parts. This thermal diffusion process infuses zinc into the surface of steel, creating a highly durable and corrosion-resistant layer. Ideal for small components and complex shapes, sherardized coatings are widely used in the construction, automotive, and rail industries for their ability to provide consistent and thorough coverage. The end result is a protective layer that not only withstands harsh environments but also maintains the dimensional integrity of the parts.

Trust and Worth

Our Clients

Our Certifications