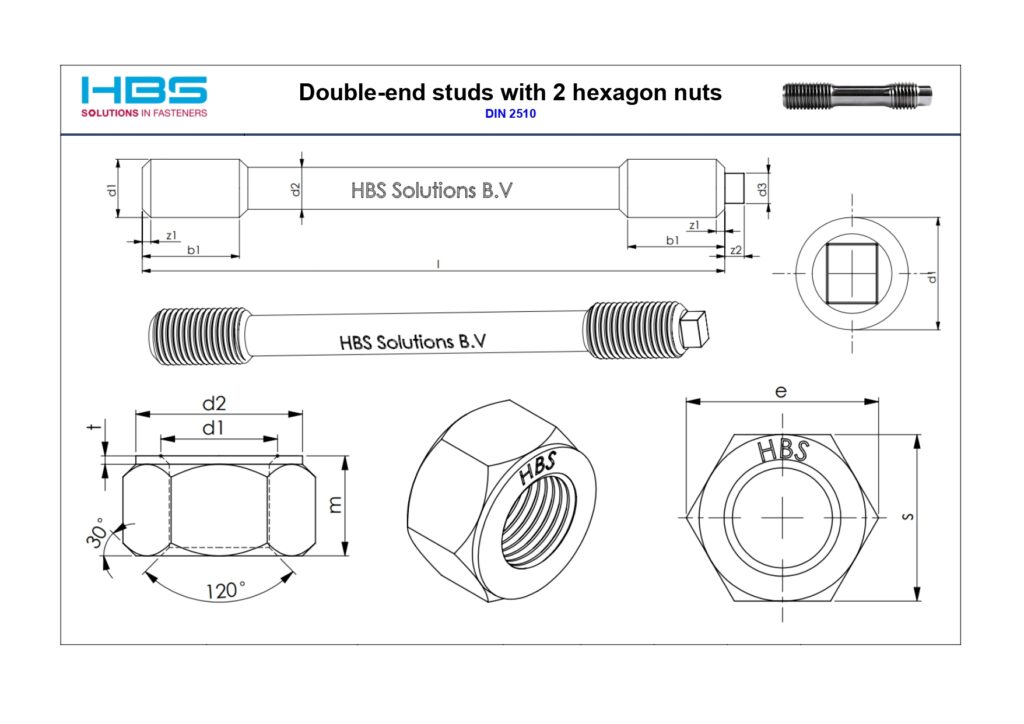

Double End Stud Bolts

Technical Specification:

- Double End Stud Bolt

- Din 2510

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Deciphering the Differences: DIN 938 vs. DIN 939 Bolts

In the intricate tapestry of fasteners, DIN 2510 bolts stand as paragons of precision and strength. Engineered to exacting standards, these bolts offer unparalleled reliability and performance in critical assembly applications. Let’s delve into the intricacies of DIN 2510 bolts and explore how they differ from DIN 938, DIN 939, and DIN 976 counterparts.

Understanding DIN 2510 Bolts:

DIN 2510 bolts, also known as double-end studs with reduced shank and thread lengths, feature a unique design tailored for demanding applications. With threads on both ends and reduced shank and thread lengths compared to standard bolts, DIN 2510 bolts offer enhanced strength and stability in critical assemblies.

Key Features of DIN 2510 Bolts:

- Reduced Shank Length: DIN 2510 bolts feature shorter shank lengths compared to standard bolts, providing increased stability and resistance to bending under heavy loads.

- Reduced Thread Length: The thread lengths of DIN 2510 bolts are also reduced, optimizing the engagement of nuts and ensuring efficient assembly while maintaining structural integrity.

- High-Strength Materials: Manufactured from high-grade materials, DIN 2510 bolts boast exceptional tensile strength and resistance to wear, corrosion, and fatigue, ensuring long-term reliability in demanding environments.

Comparison with DIN 938, DIN 939, and DIN 976 Bolts:

- DIN 938 and DIN 939 Bolts: Unlike DIN 938 and DIN 939 bolts, which feature threads on both ends with longer shank lengths, DIN 2510 bolts offer reduced shank and thread lengths for enhanced stability and strength in critical applications.

- DIN 976 Bolts: In contrast to DIN 976 bolts, which are fully threaded with no reduced shank lengths, DIN 2510 bolts feature reduced shank lengths to minimize bending and improve load-bearing capacity in critical assemblies.