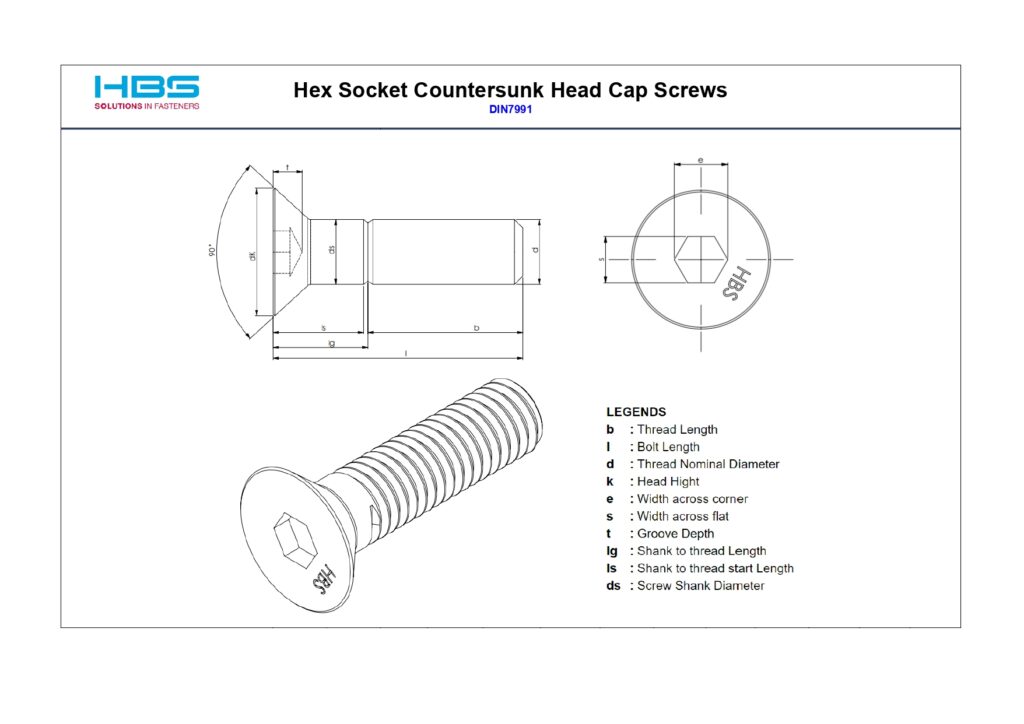

Hex Socket Countersunk Head Cap Screws

Technical Specification:

- Hex Socket Countersunk Head Cap Screws

- Din 7991

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Unveiling Precision: The DIN 7991/ISO 10642 Countersunk Screw

The DIN 7991/ISO 10642 Countersunk Screw is renowned for its versatility and durability, this screw is a cornerstone in engineering, construction, and manufacturing applications worldwide. Let’s explore the features, benefits, and applications of this indispensable fastener.

Understanding the DIN 7991/ISO 10642 Countersunk Screw:

The DIN 7991/ISO 10642 Countersunk Screw features a flat head with a conical recess, allowing it to sit flush or below the surface of the material when installed. This design minimizes protrusions and provides a smooth finish, making it ideal for applications where aesthetics and safety are crucial. Compliant with DIN 7991 and ISO 10642 standards, these screws adhere to strict dimensional tolerances, ensuring precise fit and alignment in assembly applications.

Key Features and Benefits:

- Flush Installation: The countersunk head of the DIN 7991/ISO 10642 screw allows for flush installation, providing a neat and professional appearance while reducing the risk of snagging or injury.

- Versatile Applications: From furniture assembly to machinery manufacturing, these screws find use in a wide range of industries and applications where a flush finish and reliable fastening are essential.

- Corrosion Resistance: Manufactured from high-quality materials such as stainless steel or alloy steel, DIN 7991/ISO 10642 screws offer excellent corrosion resistance, making them suitable for use in outdoor or corrosive environments.

- Easy Removal: The flat head design of the screw allows for easy removal using standard tools, simplifying maintenance and repair operations in various applications.

Applications of DIN 7991/ISO 10642 Countersunk Screws:

DIN 7991/ISO 10642 screws are utilized in diverse industries and applications, including:

- Woodworking: Used for assembling furniture, cabinets, and wooden structures where a flush finish is desired.

- Metal Fabrication: Employed in sheet metal assembly, automotive manufacturing, and structural steelwork for secure and aesthetically pleasing fastening.

- Electronics: Utilized in electronic enclosures, appliances, and consumer electronics for mounting components and securing panels.

- Marine Engineering: Trusted for marine applications such as boat building and yacht construction, where corrosion resistance and flush installation are critical.

Choosing the Right Screw for Your Needs:

When selecting fasteners for your project, consider factors such as material compatibility, load-bearing requirements, and environmental conditions. The DIN 7991/ISO 10642 Countersunk Screw offers unparalleled versatility, reliability, and aesthetic appeal, making it an ideal choice for a wide range of applications.