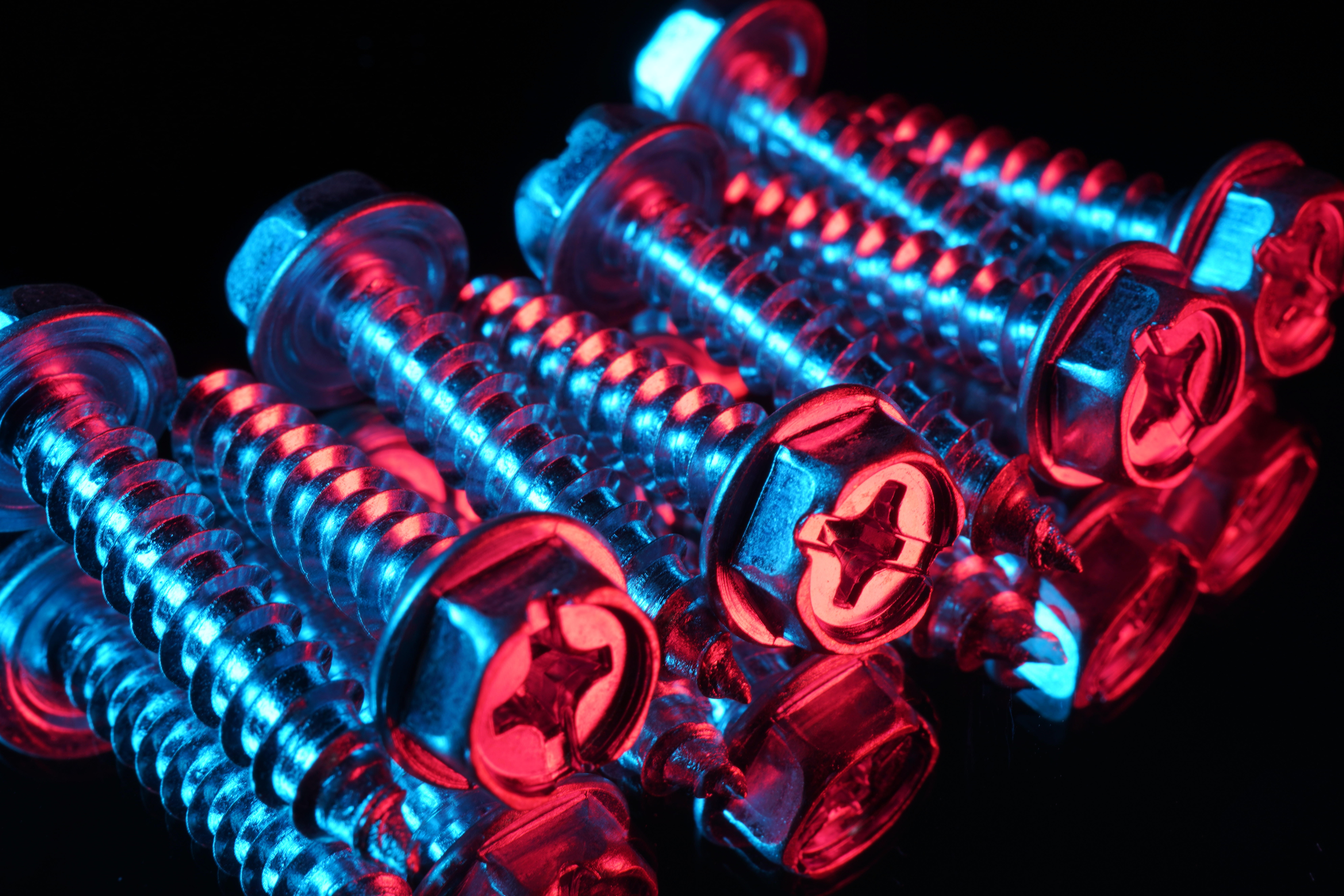

Zinc-Nickel Coatings: Superior Corrosion Protection for Demanding Environments

We are dedicated to providing advanced fastening solutions that meet the highest standards of quality and durability. Our Zinc-Nickel coated fasteners are a testament to this commitment, offering unmatched corrosion resistance and longevity, especially in harsh environmental conditions.

What are Zinc-Nickel Coatings?

Zinc-Nickel coatings consist of a metal alloy comprising approximately 85% zinc and 15% nickel. This alloy is applied to fasteners to create a robust coating that significantly enhances their corrosion resistance. The addition of nickel in the alloy provides superior protection compared to standard zinc coatings, especially in terms of resistance to rust and corrosion.

Why Choose HBS Fasteners for Zinc-Nickel Coated Fasteners?

At HBS, we take pride in our cutting-edge coating technologies. Our Zinc-Nickel coated fasteners are produced using the latest techniques to ensure the highest quality and performance. We offer a diverse range of Zinc-Nickel coated products to cater to specific industrial requirements, all backed by our commitment to excellence and customer service.

Benefits of Zinc-Nickel Coatings

Exceptional Corrosion Resistance

Zinc-Nickel coatings provide outstanding protection against corrosion, making them ideal for use in harsh and corrosive environments.

Enhanced Durability

The combination of zinc and nickel results in a tougher coating that can withstand significant wear and tear, extending the lifespan of fasteners.

Suitable for High-Temperature Environments

These coatings retain their integrity even at high temperatures, making them suitable for applications in demanding thermal conditions.

Environmentally Friendly

Zinc-Nickel coatings are an eco-conscious choice, offering effective protection without harmful environmental impacts.

Versatility

These coatings are perfect for a wide range of applications, including automotive, aerospace, and marine environments.

Applications of Zinc-Nickel Coatings

The robust properties of Zinc-Nickel coatings make them suitable for various demanding applications:

- Automotive: In vehicles, especially those exposed to corrosive substances like salt.

- Aerospace: For aircraft components requiring durability and corrosion resistance.

- Marine: Ideal for maritime equipment that faces constant exposure to saltwater.

- Industrial Machinery: Protecting machinery components in corrosive industrial environments.

Zinc-Nickel coated fasteners from HBSfasteners.nl are the ideal choice for applications demanding the highest level of corrosion resistance and durability. With superior protection in challenging environments, these fasteners ensure the longevity and reliability of your projects. Discover our range of Zinc-Nickel coated fastening solutions and experience the pinnacle of fastener technology.