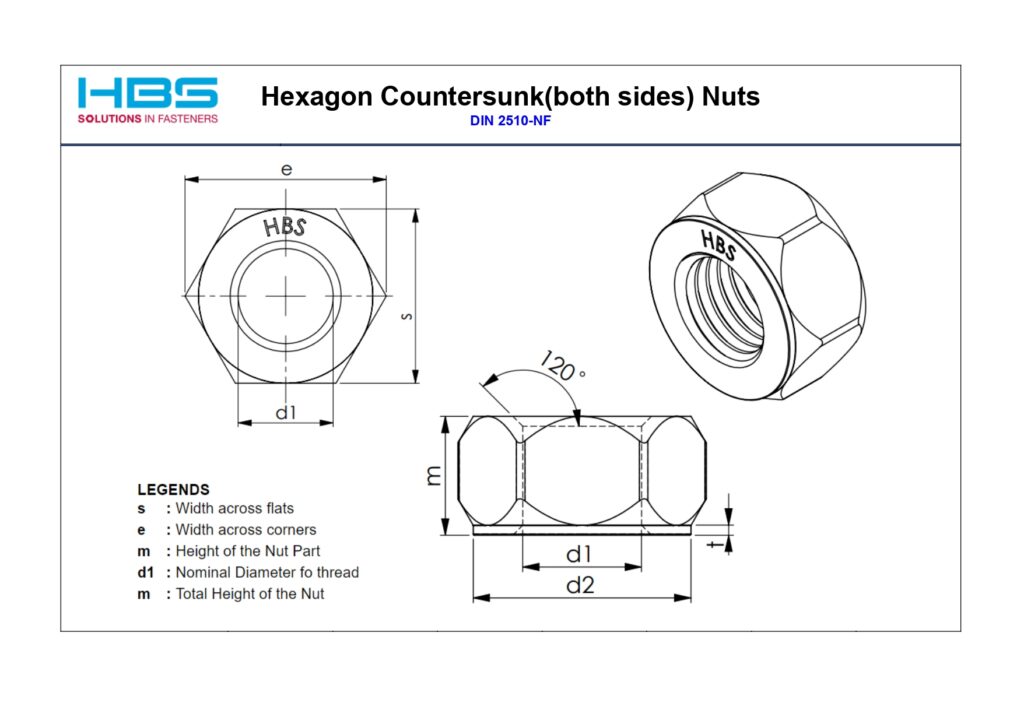

Countersunk Hexagonal Nuts

Technical Specification:

- Countersunk Hexagonal Nuts

- Din 2510-NF

- Diameter: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: St 8, 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A/SA194-2H, A/SA194-Gr.7/7M/7L/7ML,

- ANSI/ASME: A/SA194-Gr.8, A/SA194-Gr.8M

- DIN Werkstoff: 42CrMo4, 25CrMo4

- C35, CK35, C45E, C35E

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Elevating Fastening Solutions: DIN 2510 Type-NF Hex Nuts with Washer Face

In the realm of fasteners, precision and innovation converge to meet the demands of diverse applications. Among the array of options, DIN 2510 Type-NF Hex Nuts with Washer Face emerge as a specialized solution, offering enhanced performance and reliability in critical fastening scenarios. Let’s explore why, in certain applications, DIN 2510 Type-NF Hex Nuts with Washer Face are required over traditional DIN 934 and heavy-duty DIN 934 H=D nuts.

Understanding DIN 2510 Type-NF Hex Nuts with Washer Face:

DIN 2510 Type-NF Hex Nuts with Washer Face represent a refined evolution of traditional hex nuts, featuring an integrated washer face beneath the nut. This unique design element serves to distribute pressure more evenly across the mating surface, reducing the risk of surface damage and providing a more secure and stable connection. These nuts adhere to DIN 2510 standards, ensuring strict compliance with industry specifications.

Advantages over DIN 934 and DIN 934 H=D Nuts:

- Improved Load Distribution: The washer face of DIN 2510 Type-NF Hex Nuts acts as a buffer between the nut and the mating surface, spreading the load over a larger area. This minimizes the risk of surface deformation or damage, making it particularly suitable for softer materials or fragile surfaces.

- Enhanced Stability: By providing a larger contact area, the washer face increases the stability and resistance to loosening of the nut, even under dynamic or vibrating conditions. This is especially beneficial in applications subject to constant movement or mechanical stress.

- Streamlined Assembly: DIN 2510 Type-NF Hex Nuts with Washer Face offer a simplified assembly process compared to using separate washers with standard nuts. This reduces the number of components and potential points of failure, streamlining the installation process and enhancing overall efficiency.

Recommended Use Cases for DIN 2510 Type-NF Hex Nuts with Washer Face:

- Structural Engineering: Essential for critical fastening applications in structural steelwork, where stability, load distribution, and surface protection are paramount.

- Heavy Machinery: Ideal for securing components in heavy machinery and equipment subjected to high loads, vibrations, or thermal expansion, ensuring reliable performance and longevity.

- Pipeline Installations: Crucial for pipeline installations and connections, where maintaining tight seals and preventing leakage is essential for safety and integrity.