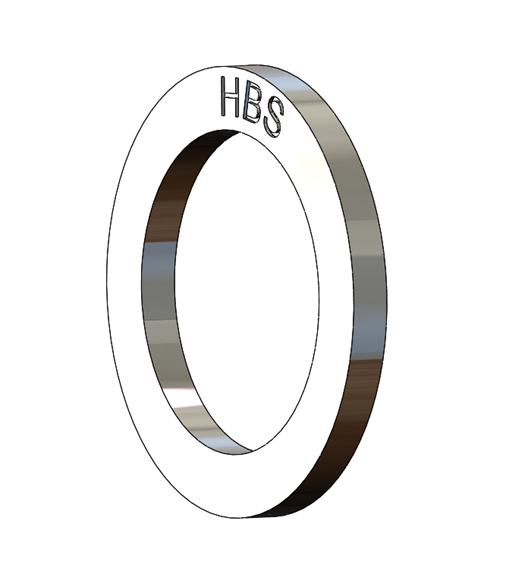

Seal Ring Form-A

Technical Specification:

- Seal Ring Form-A

- DIN 7603-A

- Diameter: Metric or Inch

Possible materials:

- ISO: St 4.8/ 5.6 / 8/ 10/ 10.9/ 12/ 12.9

- ISO: A2,A4, 304L, 316L

- ANSI/ASME: A/SA193-B7/ B7M/ L7/ L7M/ B8/ B8M

- ANSI/ASME: A/SA194 2H/ Gr.8/ Gr.8M

- Alloy: Monel-400, Alloy-201, Inconel-625

- Non-Alloy: CS, Soft Iron, Armco, Titanium, Graphite, Non-Asbestos

- DIN Werkstoff: 25CrMo4, 42CrMo4 , X5CrNiMo17-12-2, X5CrNi 18-10, X36CrMo17

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Exploring DIN 7603A Sealing Washers/Gaskets: Enhancing Precision in Mechanical Seals

In the intricate landscape of mechanical engineering, where precision is paramount and reliability is non-negotiable, DIN 7603A Sealing Washers/Gaskets emerge as essential components, elevating the integrity of countless assemblies with their specialized sealing prowess. These unassuming yet crucial washers play a pivotal role in ensuring leak-proof connections, safeguarding against fluid seepage, and upholding operational efficiency across diverse applications. Let’s embark on an enlightening journey to delve into the unique characteristics, applications, and benefits of DIN 7603A Sealing Washers/Gaskets, where each compression signifies a seal of excellence.

Unveiling Specialization:

DIN 7603A Sealing Washers/Gaskets represent a specialized category of sealing components meticulously engineered to meet stringent standards and specifications. These washers typically feature a precise profile and material composition optimized for creating reliable seals in specific applications, such as hydraulic systems, automotive engines, and plumbing fixtures.

Tailored Precision:

At the heart of every DIN 7603A sealing washer lies a commitment to tailored precision, where dimensions, material properties, and surface finishes are meticulously calibrated to achieve optimal sealing performance. Whether crafted from copper, aluminum, or other materials, these washers undergo stringent manufacturing processes to ensure uniformity, consistency, and reliability in sealing critical joints and connections.

Versatility in Applications:

DIN 7603A Sealing Washers/Gaskets find application across a diverse spectrum of industries and environments where secure sealing is essential. From hydraulic systems in heavy machinery to automotive engines and industrial pipelines, these washers play a crucial role in preventing leaks, maintaining system integrity, and ensuring operational safety and efficiency.

Enhanced Sealing Efficiency:

With their specialized design and precision engineering, DIN 7603A offers enhanced sealing efficiency compared to conventional washers or gaskets. Their ability to conform to irregularities in mating surfaces, resist deformation under pressure, and provide reliable sealing even in demanding conditions makes them indispensable components in critical sealing applications.

Compliance and Reliability:

DIN 7603A Sealing Washers/Gaskets adhere to strict quality standards and specifications, ensuring compliance with regulatory requirements and industry norms. Their consistent performance, reliability, and durability make them trusted components in critical systems where safety, performance, and compliance are paramount considerations.