EPK

EPK

What is EPK?

EPK is a specialized process applied to fasteners, making them suitable for cleanroom use. This process involves precision cleaning, deburring, and often passivation, to ensure the fasteners meet strict cleanliness standards. EPK fasteners are essential in environments like semiconductor manufacturing and pharmaceutical production, where contamination control is crucial.

An Electronic Packaging Cleanroom (EPK Cleanroom) is a highly controlled environment specifically designed for the manufacturing and assembling of electronic components and systems. This type of cleanroom is crucial in industries where even microscopic particles can adversely affect the manufacturing process, such as in semiconductor fabrication, pharmaceuticals, and aerospace engineering.

The primary purpose of an EPK cleanroom is to maintain an extremely low level of environmental pollutants such as dust, airborne microbes, aerosol particles, and chemical vapors. This is achieved through sophisticated air filtration systems, including HEPA (High Efficiency Particulate Air) and ULPA (Ultra Low Particulate Air) filters, which remove contaminants from the air.

EPK Fasteners

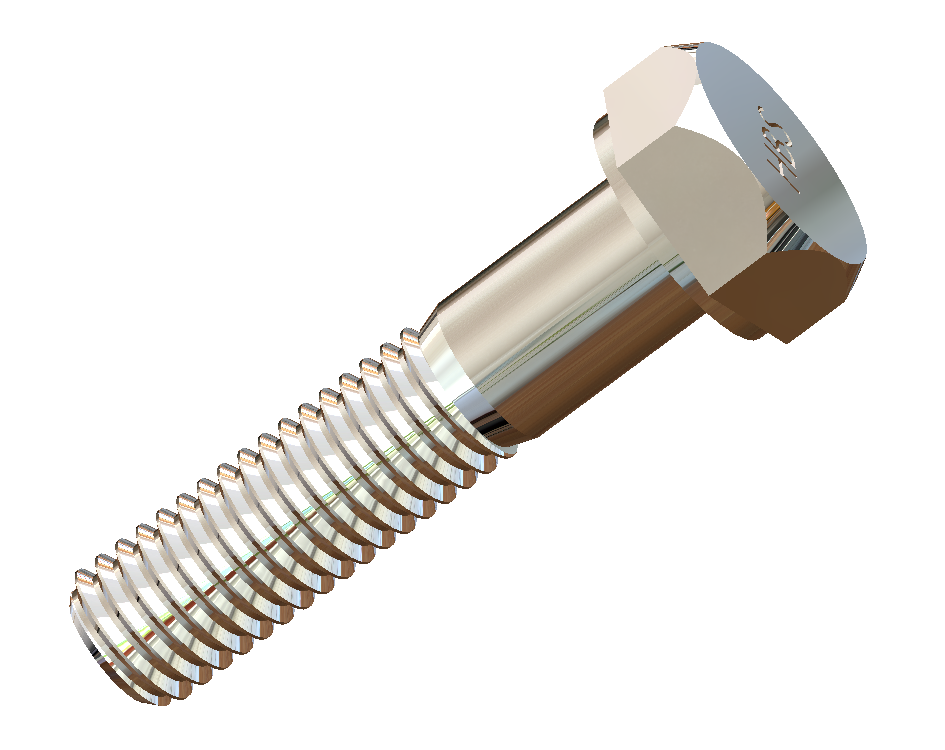

EPK Fasteners refer to a specialized category of fastening solutions designed for use in a variety of industries, including automotive, construction, aerospace, and machinery manufacturing. The term “EPK” is often associated with high-quality, precision-engineered fasteners that meet stringent industry standards and requirements. These fasteners are essential in applications where reliability, strength, and durability are critical.

Key characteristics of EPK Fasteners

Material Quality

EPK Fasteners are typically made from high-grade materials such as stainless steel, carbon steel, titanium, or specialized alloys. These materials are chosen for their strength, corrosion resistance, and ability to withstand extreme temperatures and environmental conditions.

Precision Engineering

These fasteners are manufactured with precise tolerances to ensure a perfect fit and optimal performance in their specific applications. Precision engineering is crucial in industries like aerospace and automotive, where the integrity of each component is vital.

Variety of Types

The range of EPK Fasteners is extensive, including bolts, screws, nuts, washers, rivets, and specialized fasteners. Each type is designed for specific applications, taking into account factors like load-bearing capacity, environmental exposure, and required torque.

Customization

Many manufacturers of EPK Fasteners offer custom solutions to meet unique requirements of specific projects or applications. This might involve custom sizes, shapes, or even specially formulated materials.

Compliance with Standards

EPK Fasteners are often produced in compliance with international and industry-specific standards such as ISO, DIN, ASTM, or SAE. This ensures compatibility and reliability across different applications and industries.

Applications

These fasteners are used in critical applications where failure can lead to significant consequences. For instance, in the automotive industry, they are used in engines and transmission systems, while in construction, they are essential for structural integrity.

Innovation and Technology

The manufacturing of EPK Fasteners often involves cutting-edge technologies and continuous innovation to improve performance, reduce weight, and enhance resistance to wear and tear.

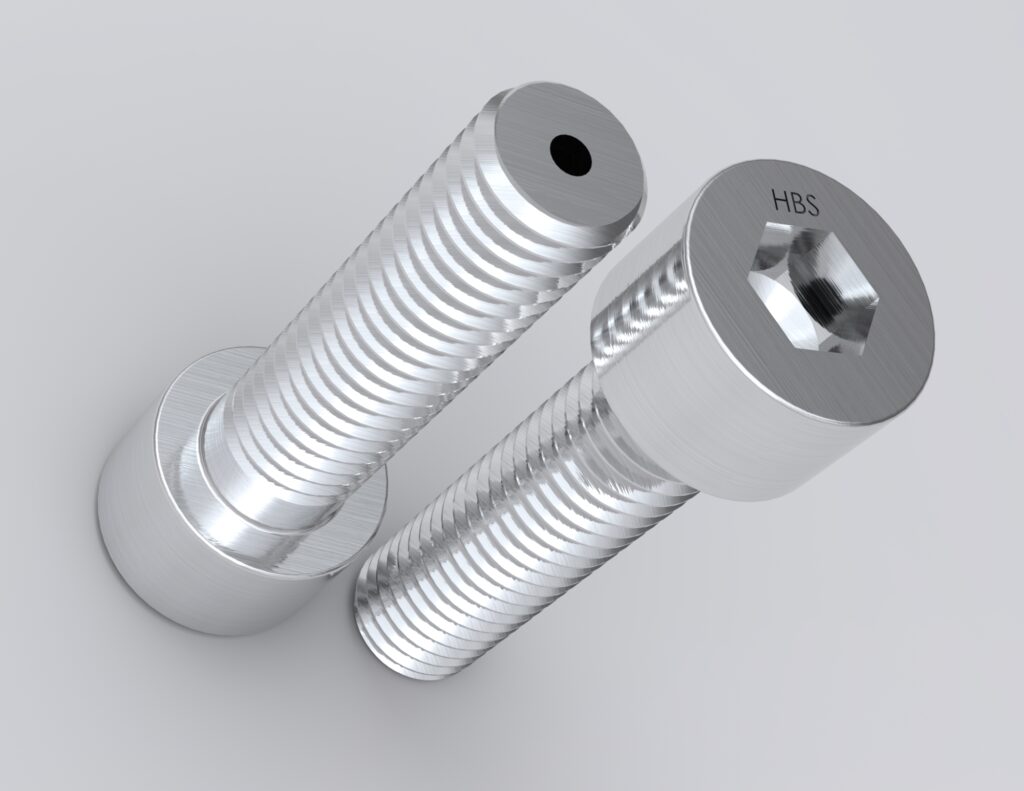

Vented Design

The vented design of EPK Fasteners is a specialized feature that enhances their performance in specific applications. These fasteners are engineered with a unique venting mechanism, typically a small hole or a series of holes, which allows for the release of trapped gases or pressure. This design is particularly beneficial in high-pressure environments or in applications where outgassing can be an issue, such as in vacuum sealing or aerospace applications. By allowing gases to escape, the vented design prevents pressure buildup and potential damage to the assembly, ensuring a more secure and reliable fastening solution. The inclusion of this feature in EPK Fasteners showcases their commitment to innovation and addressing specific industry challenges.