Our Products

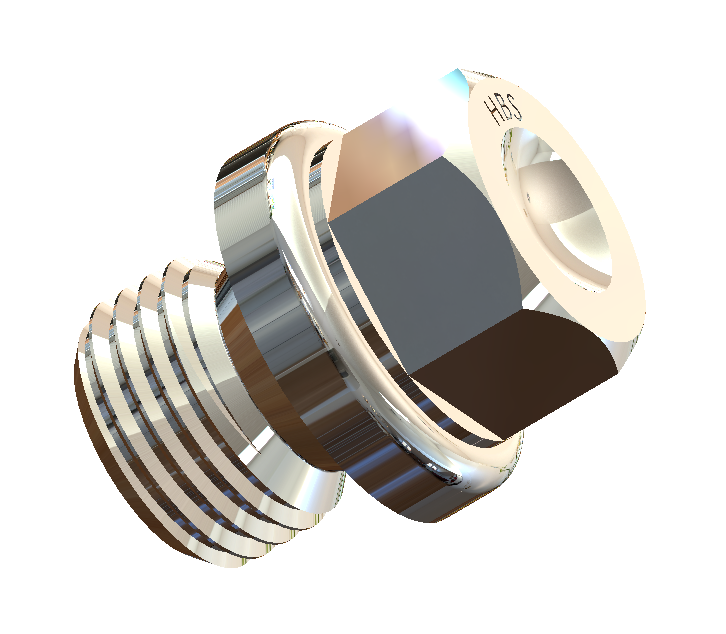

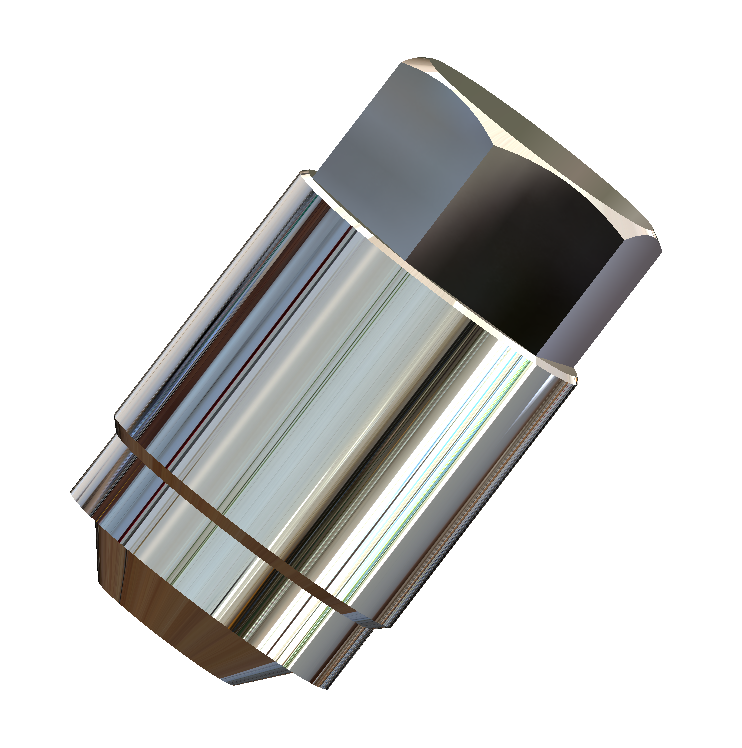

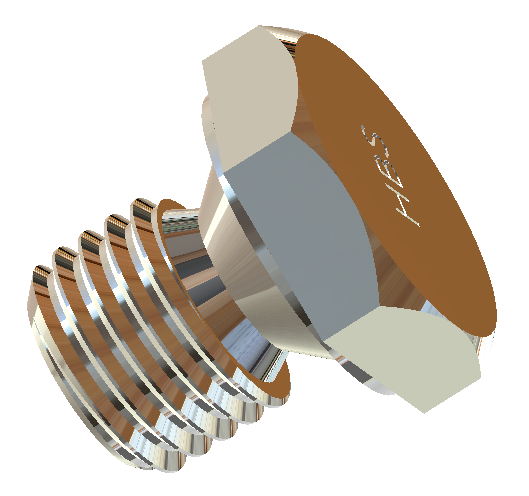

Explore our Header Plugs

Unveiling the Vital Role of Header Plugs in Heat Exchangers and Air Coolers

In the intricate machinery of heat exchangers and air coolers, where efficiency and reliability are paramount, header plugs emerge as unsung heroes, ensuring seamless operation and optimal performance. These small yet mighty components play a pivotal role in maintaining the integrity of critical systems, safeguarding against leaks, and facilitating efficient heat transfer. Let’s delve into the immense importance of header plugs in heat exchangers, air coolers, and similar applications, where each plug represents a crucial element in the intricate web of thermal management.

Sealing Integrity and Leak Prevention:

Header plugs serve as essential sealing elements within heat exchangers and air coolers, ensuring the integrity of fluid passages and preventing leakage of coolant or process fluid. Installed at the ends of headers and tubesheets, these plugs create a tight seal, effectively containing the flow of fluids within the system. By maintaining sealing integrity, header plugs minimize the risk of fluid loss, contamination, and environmental damage, safeguarding the efficiency and safety of heat exchange processes.

Pressure and Temperature Resistance:

In environments subjected to high pressures and temperatures, such as industrial heat exchangers and air coolers, header plugs must withstand extreme operating conditions without compromising performance. Constructed from durable materials such as stainless steel, brass, or corrosion-resistant alloys, these plugs exhibit exceptional strength and resilience, allowing them to endure the rigors of demanding applications. Their ability to withstand elevated pressures and temperatures ensures long-term reliability and uninterrupted operation of heat exchange systems.

Facilitating Maintenance and Serviceability:

Header plugs play a crucial role in facilitating maintenance, inspection, and servicing of heat exchangers and air coolers. These plugs can be easily removed to access internal components for cleaning, repair, or replacement, allowing maintenance personnel to conduct routine inspections and address any issues promptly. Their threaded design enables quick and hassle-free installation and removal, minimizing downtime and optimizing system uptime.

Enhancing Efficiency and Performance:

By maintaining sealing integrity, header plugs contribute to the overall efficiency and performance of heat exchange systems. By preventing leaks and ensuring proper fluid flow, these plugs help maximize heat transfer rates, enhance energy efficiency, and optimize thermal management processes. Whether in industrial processes, HVAC systems, or automotive radiators, header plugs play a vital role in achieving optimal performance and operational efficiency.