Heavy Hexagon Structural Bolt

Technical Specification:

- Heavy Hexagon Structural Bolt

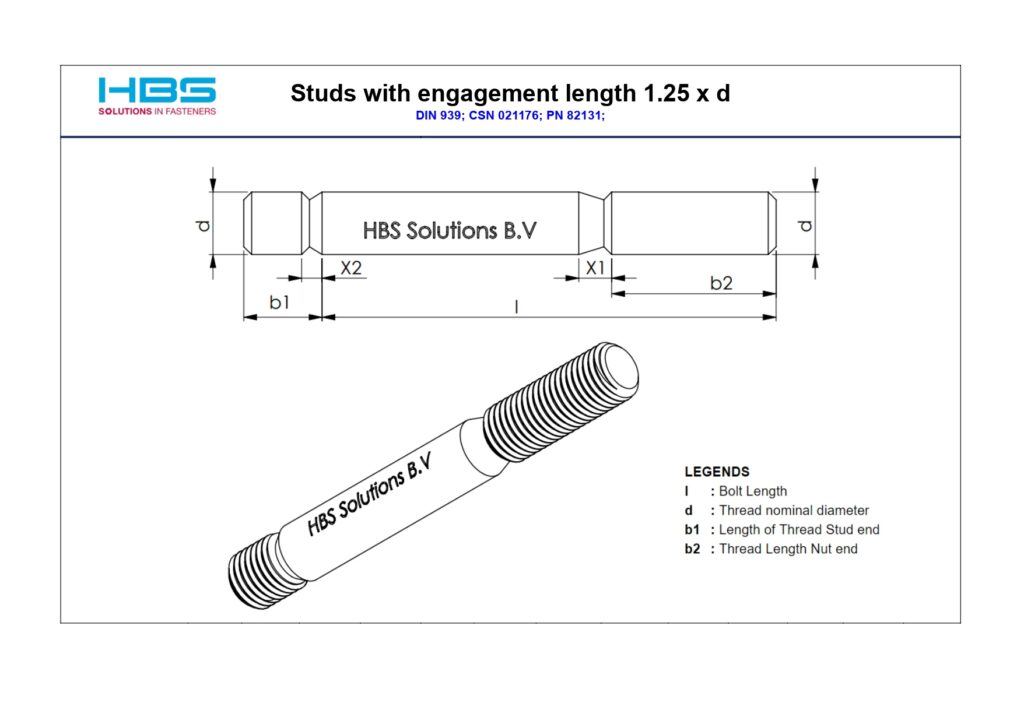

- Din 939

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Deciphering the Differences: DIN 938 vs. DIN 939 Bolts

Where precision and strength are paramount, understanding the distinctions between different types of bolts is essential. Let’s delve into the differences between DIN 938 and DIN 939 bolts, exploring their unique features and applications.

DIN 938 Bolts:

DIN 938 bolts, also known as double-ended studs, feature threads on both ends with an unthreaded shank in the middle. This design allows for the simultaneous connection of two components without the need for additional nuts. DIN 938 bolts excel in applications requiring efficient assembly and disassembly processes, offering versatility and reliability in various industries.

DIN 939 Bolts:

On the other hand, DIN 939 bolts share similarities with DIN 938 bolts, boasting threads on both ends and an unthreaded shank in the middle. However, DIN 939 bolts typically feature longer unthreaded shank lengths compared to DIN 938 bolts. This extended shank provides added stability and strength in applications where a longer grip length is required.

Key Differences:

- Shank Length: The primary difference between DIN 938 and DIN 939 bolts lies in the length of the unthreaded shank. DIN 938 bolts typically have shorter unthreaded shanks, while DIN 939 bolts feature longer unthreaded shanks for enhanced stability and strength.

- Applications: DIN 938 bolts are well-suited for applications where efficient assembly and disassembly are priorities, while DIN 939 bolts are preferred in scenarios requiring a longer grip length and additional stability.

Choosing the Right Bolt for Your Needs:

When selecting bolts for your project, consider the specific requirements and demands of your application. If you prioritize efficient assembly and disassembly processes, DIN 938 bolts may be the ideal choice. However, if you require added stability and strength with a longer grip length, DIN 939 bolts are a suitable option.