Unlocking the Potential of DIN 931 Fasteners

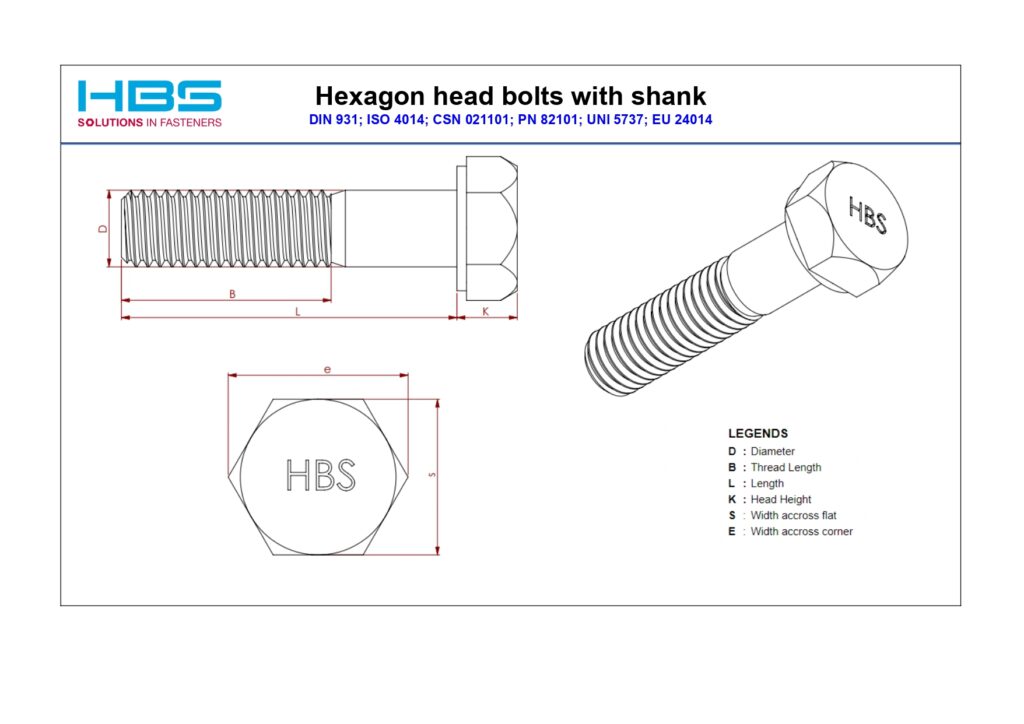

DIN 931 is a mechanical standard, which specifies the properties and dimensions of hexagon head bolts with partial thread. DIN 931is a German standard, also known as Deutsches Institut für Normung (DIN) 931, and is commonly used in engineering and construction applications. The equivalent ISO standard is 4014.

These bolts are made of carbon steel or alloy steel and have a hexagonal head, which makes them easy to tighten and loosen with a wrench or socket. The partial thread means that only a portion of the bolt is threaded, leaving the rest of the shaft smooth.

The DIN 931 defines the dimensions of the bolt, including the length, diameter, and thread pitch. It also sets requirements for the mechanical properties, such as the tensile strength and hardness, and the surface finish.

Uses of DIN 931

DIN 931 bolts are commonly used in a wide range of applications in various industries, including construction, manufacturing, and automotive. Some of the common uses of DIN 931 bolts are:

- Structural applications: DIN 931 bolts are often used in construction applications for fastening structural steel members, such as beams, columns, and trusses.

- Machinery and equipment assembly: They are used in the assembly of heavy machinery and equipment, such as engines, turbines, and generators.

- Automotive industry: This hex bolts are used in the automotive industry for fastening engine components, chassis parts, and suspension systems.

- Aerospace: In the aerospace industry these are used for fastening aircraft components and structures.

- Marine applications: Marine engineers uses this in marine applications for fastening deck hardware, rigging, and other structural components.

Materials for DIN 931

DIN 931 bolts are available in a variety of materials, and different standards specify the requirements for each material. Here are some of the commonly used materials for DIN 931 bolts, along with the corresponding standards:

Materials specified by ANSI/ASME standards:

- ASTM A193 Grade B7: This material is a high-strength alloy steel used in applications where high tensile strength and resistance to corrosion are required.

- ASTM A320 Grade L7: This material is a low-temperature steel used in applications where the bolt needs to perform in cold environments.

Materials specified by ASTM standards:

- ASTM A307 Grade A: This material is a carbon steel used in general-purpose applications that do not require high strength or resistance to corrosion.

- ASTM A325 Type 1: This material is a high-strength steel used in structural applications.

- ASTM A490 Type 1: This material is a high-strength steel used in heavy construction applications.

Materials specified by DIN standards:

- Steel Grade 8.8: This is a medium carbon steel that has a tensile strength of 800 N/mm² and is commonly used in general-purpose applications.

- Steel Grade 10.9: This is a high-strength steel that has a tensile strength of 1000 N/mm² and is commonly used in automotive and machinery applications.

- Steel Grade 12.9: This is a very high-strength steel that has a tensile strength of 1200 N/mm² and is commonly used in aerospace and other critical applications.

The choice of material for DIN 931 bolts will depend on the specific requirements of the application, including the load-bearing capacity, environmental conditions, and corrosion resistance.

Pickling and Passivation: Spotless surface and weatherproof coating for stainless-steel fasteners. A suitable surface treatment is crucial to guaranteeing the performance and lifespan of fasteners. Two popular techniques for this

Title: Gr.4 Cleaning Services: Exceptional Solutions for Fastener Surface Preparation Considering your trusted partner for comprehensive fastening solutions. Among our range of services, Gr.4 cleaning stands out as an essential

Grade 2 Cleaning Fasteners: The Epitome of Purity for High-Performance Industries In the world of assembly, the cleanliness of fasteners is not just a requirement but a necessity for ensuring

cleanroom HBS is the one stop Solution for Fasteners EPK Fasteners for EPK Cleanroom Explore more Gr.4 Cleaned Gr.4 Cleaned Cleanroom Fasteners Explore more Gr.2 Cleaned Gr.2 Cleaned Cleanroom Fasteners

EPK Fasteners Our Services Lorem ipsum dolor sit amet, consectetur adipiscing elit. Socketed Head Cap Screws for EPK The challenge was to craft such a complex fastener having such a

Sherardizing Coatings Among our array of products, Sherardizing coatings shine as a proven method for enhancing the durability and longevity of fasteners. With their time-tested performance and exceptional resistance to

Hot-Dip Galvanized Coatings As your trusted source for premium industrial fastening solutions. Among our comprehensive selection of products, Hot-Dip Galvanized coatings stand out as a reliable and proven method for

Geomet-500 HBS can be your premier destination for high-quality industrial fastening solutions. Among our comprehensive range of products, Geomet-500 coatings stand out as a testament to innovation and performance. Engineered

Zinc-Nickel Coatings: Superior Corrosion Protection for Demanding Environments We are dedicated to providing advanced fastening solutions that meet the highest standards of quality and durability. Our Zinc-Nickel coated fasteners are

Zinc Plated We specialize in providing top-tier fastening solutions. Among our diverse product range, Zinc Plated fasteners stand out as a popular and cost-effective choice for a wide array of