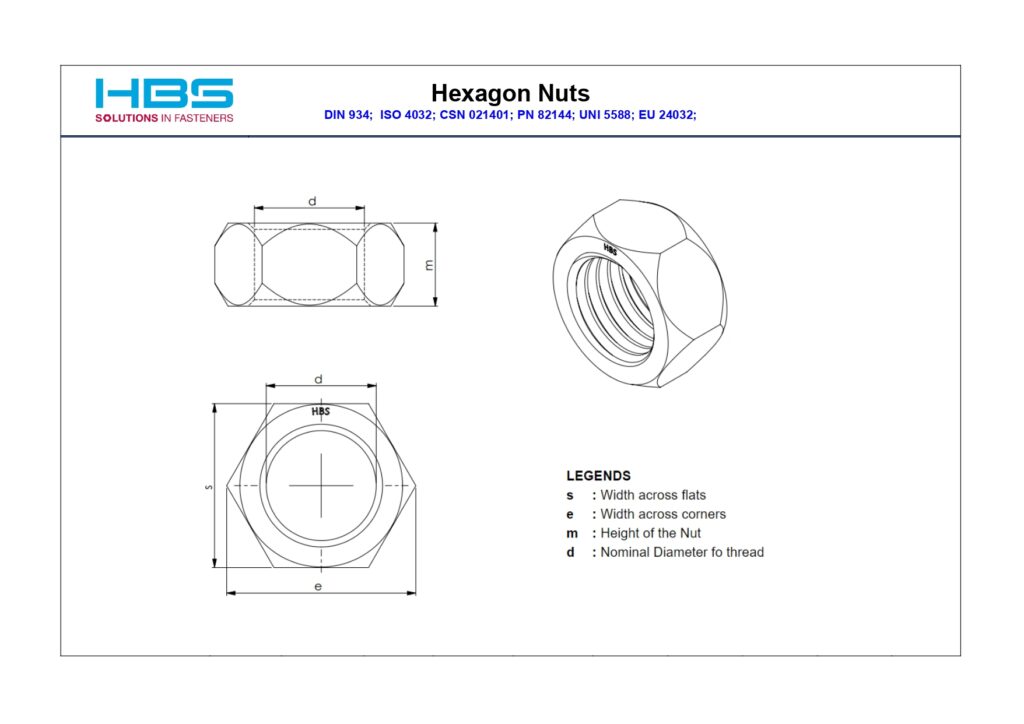

Heavy Hexagonal Nuts

Technical Specification:

- Heavy Hexagonal Nuts

- Din 934 H=D

- Diameter: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: St 8, 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A/SA194-2H, A/SA194-Gr.7/7M/7L/7ML,

- ANSI/ASME: A/SA194-Gr.8, A/SA194-Gr.8M

- DIN Werkstoff: 42CrMo4, 25CrMo4

- C35, CK35, C45E, C35E

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Understanding the DIN 934 H=D Heavy Hex Nut

The DIN 934 H=D Heavy Hex Nut shares the same hexagonal shape and internal threading as the traditional DIN 934 nut. However, what sets it apart is its increased height (H) and diameter (D), providing greater surface area and increased material thickness. This enhanced design translates to higher tensile strength and improved resistance to deformation under heavy loads.

Key Advantages over Normal DIN 934 Nuts:

- Enhanced Load-Bearing Capacity: The increased height and diameter of the DIN 934 H=D Heavy Hex Nut result in a larger contact area with the bolt or threaded rod. This additional surface area distributes the load more evenly, reducing the risk of bolt failure or nut deformation under high-stress conditions.

- Greater Stability and Durability: With thicker walls and a sturdier construction, the DIN 934 H=D Heavy Hex Nut offers enhanced resistance to vibration, loosening, and corrosion. This makes it an ideal choice for applications subject to harsh operating environments or frequent mechanical stress.

- Compliance with Specific Requirements: In some cases, engineering specifications or industry standards may call for the use of heavy hex nuts due to their superior strength characteristics. The DIN 934 H=D Heavy Hex Nut ensures compliance with these requirements, providing peace of mind in critical applications.

Applications Where DIN 934 H=D Heavy Hex Nuts Excel:

- Structural Engineering: Used in bridge construction, steel fabrication, and structural steelwork where high tensile strength and reliability are essential.

- Heavy Machinery: Trusted for securing critical components in heavy machinery, equipment, and industrial plants subject to heavy loads and dynamic forces.

- Infrastructure Projects: Employed in infrastructure projects such as railways, highways, and power plants, where safety and durability are paramount.