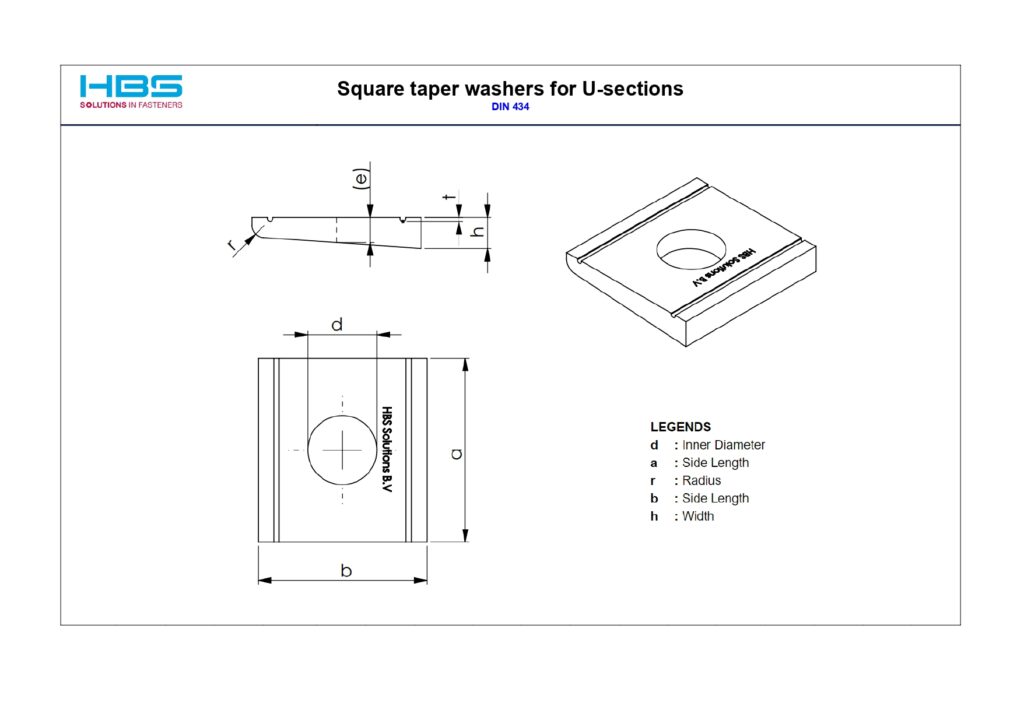

Square taper Washers

Technical Specification:

- Square taper Washers

- DIN 434

- Diameter: Metric or Inch

- Length: Metric or Inch

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Elevating Fastener Precision: DIN 434 Square Taper Washer

DIN 434 Square Taper Washer is a specialized component, offers unique advantages in specific applications. Renowned for its square shape and tapered design, this washer plays a crucial role in aligning and securing fastener connections, distinguishing itself from conventional washers such as DIN 125, DIN 127, DIN 6916, and DIN 9021. Let’s explore the characteristics, applications, and key distinctions of DIN 434, unveiling its significance in enhancing fastener precision.

Characteristics of DIN 434 Square Taper Washer:

DIN 434 Square Taper Washer is characterized by its square shape and tapered profile, featuring a larger outer diameter and a narrower inner diameter. These washers are designed to provide precise alignment and support to fastener connections, particularly in applications where square or rectangular holes are present. Manufactured from high-quality materials such as steel or stainless steel, DIN 434 washers offer durability and reliability in various operating conditions.Applications and Versatility:

DIN 434 Square Taper Washer finds specialized application in industries and sectors where precise alignment and secure fastener connections are essential. Some common applications include:- Woodworking and Joinery: In woodworking and joinery projects, DIN 434 washers are used to secure bolts and screws in square or rectangular holes, ensuring precise alignment and preventing fastener rotation. Their tapered design helps guide the fastener into position, enhancing assembly accuracy and stability.

- Metal Fabrication and Construction: DIN 434 washers find application in metal fabrication and construction projects where square or rectangular holes are present in structural components. They provide essential support and alignment to fasteners in beams, channels, and framework assemblies, ensuring optimal load distribution and structural integrity.

- Machinery and Equipment Installation: In machinery and equipment installation, DIN 434 washers are employed to secure bolts and screws in mounting brackets, panels, and machine frames. Their tapered profile helps center the fastener in square or rectangular holes, reducing the risk of misalignment and ensuring reliable performance under dynamic loads and vibrations.

Key Distinctions from Conventional Washers:

- Square Shape: Unlike round washers such as DIN 125, DIN 127, DIN 6916, and DIN 9021, DIN 434 Square Taper Washer features a square shape. This square profile provides enhanced stability and alignment in applications where square or rectangular holes are present, ensuring precise fastener positioning and preventing rotation.

- Tapered Design: DIN 434 washers are characterized by their tapered profile, with a larger outer diameter and a narrower inner diameter. This tapered design helps guide the fastener into position and ensures snug fitment in square or rectangular holes, minimizing play and enhancing fastener stability.