Imperial Socket Head Screws

Technical Specification:

- Imperial Socket Head Screws

- ASME B18.3

- Fully Threaded

- Diameter: Metric or Inch

- Length: Metric or Inch

- Thread: Coarse or Fine

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

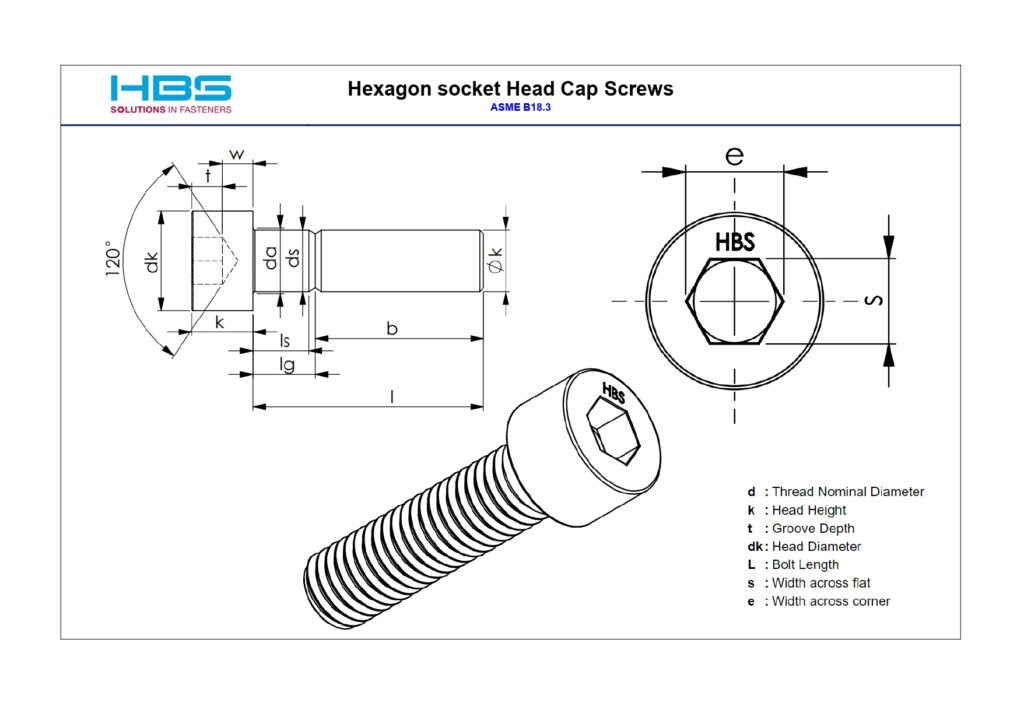

Understanding ASME B18.3 Socket Set Screws

ASME B18.3 Socket Set Screws are internally threaded fasteners with a hexagonal drive socket at one end and a cup, flat, or cone point at the opposite end. This unique design allows for secure fastening into a tapped hole or against a flat surface, providing excellent clamping force and resistance to loosening under load. Manufactured to ASME B18.3 standards, these screws adhere to strict dimensional tolerances, ensuring consistent quality and performance in critical applications.

Key Features and Benefits:

- Secure Fastening: The hexagonal drive socket of ASME B18.3 Socket Set Screws allows for efficient tightening using an Allen wrench or hex key, ensuring a secure and reliable connection.

- Versatile Applications: From machinery assembly to automotive engineering, these screws find use in a wide range of industries and applications where precise positioning and clamping are essential.

- Point Options: ASME B18.3 Socket Set Screws are available with various point options, including cup, flat, and cone points, allowing for customization based on specific application requirements.

- High-Strength Materials: Manufactured from high-grade materials such as alloy steel or stainless steel, these screws offer exceptional tensile strength, corrosion resistance, and durability, making them suitable for use in demanding environments.

Applications of ASME B18.3 Socket Set Screws:

ASME B18.3 Socket Set Screws are utilized in diverse industries and applications, including:- Machinery Assembly: Used for securing shafts, gears, and pulleys in machinery and equipment assembly, ensuring precise alignment and operation.

- Automotive Manufacturing: Employed in automotive transmission systems, steering components, and engine assemblies for precise adjustment and positioning.

- Construction: Trusted for structural fastening applications in construction projects, including steel fabrication, timber framing, and architectural installations.

- Electronics: Utilized in electronic enclosures, appliances, and consumer electronics for mounting components and securing panels with minimal protrusion.