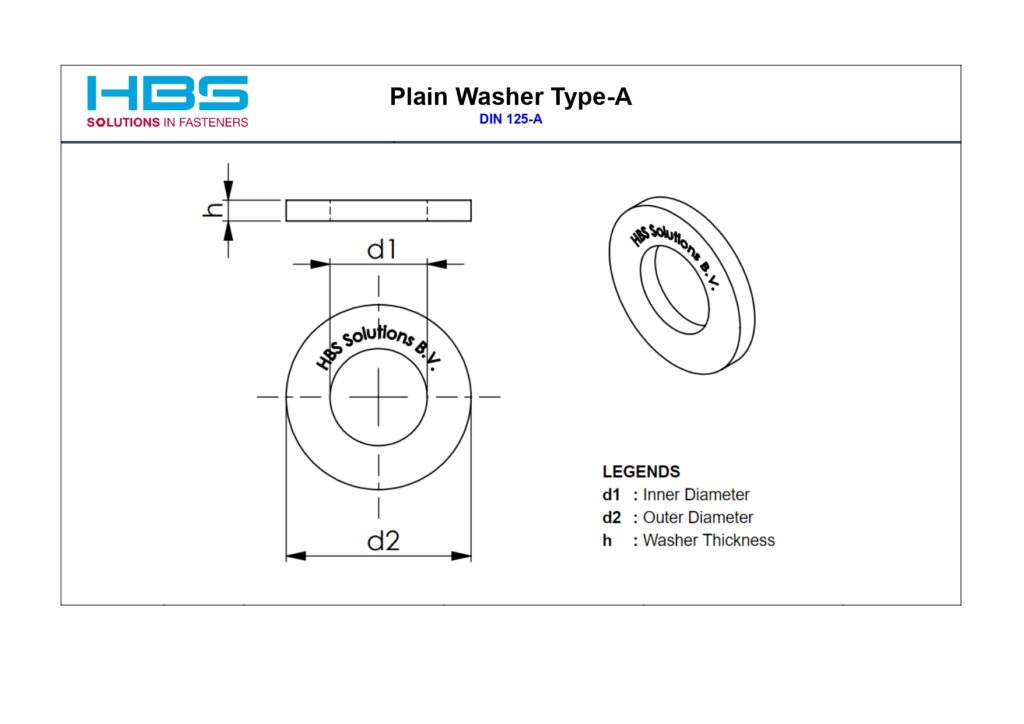

Plain Washer Form-A

Technical Specification:

- Plain Washer

- DIN 125 A

- Diameter: Metric or Inch

- Thickness: Metric or Inch

Possible materials:

- ISO: 8.8., 10.9, 12.9

- ISO: A2, A4

- ANSI/ASME: A193-B7, A320-L7, A307

- ANSI/ASME: A193-B8(M) Cl.1 & Cl.2

- DIN Werkstoff: 42CrMo4, 25CrMo4

Possible coatings:

- Carbon steel: Hot-dip Galvanizing, Geomet-500, Zinc, Zinc-Nickel, PTFE/Xylan, TAKECOAT-1000

- Stainless steel: PTFE/Xylan, TAKECOAT-1000

Applications:

- Structural

- Machinery equipment

- Automotive

- Aerospace

Characteristics of DIN 125-A Plain Washer Type-A

DIN 125-A Plain Washer Type-A is defined by its simple yet versatile design, featuring a flat, circular shape with a centrally located hole. These washers are typically manufactured from high-quality materials such as steel, stainless steel, or brass, ensuring durability and reliability in various operating conditions. The outer diameter (OD), inner diameter (ID), and thickness of DIN 125-A washers adhere to standard specifications outlined by the Deutsches Institut für Normung (DIN), providing consistency and interchangeability in fastener applications.

Applications and Versatility:

DIN 125-A Plain Washer Type-A finds widespread application across industries and sectors where secure and reliable fastener connections are essential. Some common applications include:

- General Fastening Applications: DIN 125-A washers are used in a wide range of fastening applications, including bolts, screws, nuts, and threaded rods. They provide a smooth bearing surface under the head of the fastener or the nut, distributing loads evenly and reducing the risk of surface damage or deformation.

- Construction and Building Industry: In construction and building projects, DIN 125-A washers are employed to reinforce connections in structural elements such as beams, columns, and joints. They help prevent loosening of fasteners due to vibration, thermal expansion, or dynamic loads, ensuring structural stability and safety.

- Automotive and Machinery Assemblies: DIN 125-A washers play a vital role in automotive and machinery assemblies, where they provide additional support and load distribution in critical components such as engine mounts, chassis connections, and machinery frames. Their durability and resistance to corrosion make them suitable for demanding operating environments.

- Electrical and Electronic Equipment: In electrical and electronic applications, DIN 125-A washers serve as insulating barriers between fasteners and sensitive components, protecting against electrical conductivity and potential short circuits. They are commonly used in panel assemblies, control cabinets, and electrical enclosures.

Significance in Fastener Integrity:

DIN 125-A Plain Washer Type-A is more than just a component—it’s a symbol of stability, reliability, and precision engineering in fastener assemblies. By distributing loads, protecting surfaces, and enhancing the performance of fasteners, DIN 125-A washers ensure the integrity and longevity of connections in diverse applications. Their adherence to standard specifications and consistent quality make them a trusted choice for engineers, contractors, and manufacturers seeking dependable fastening solutions.