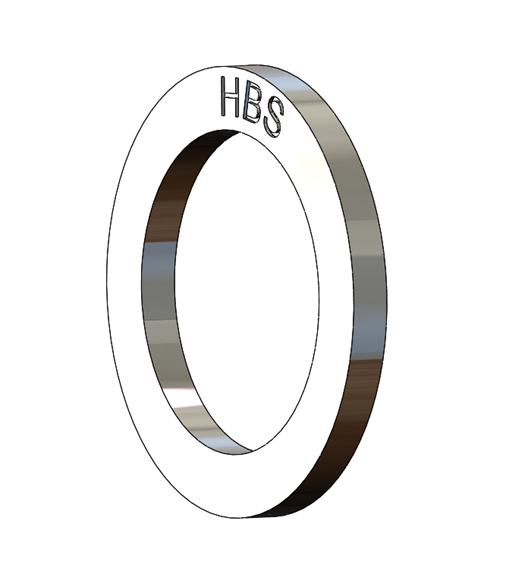

Our Products

Explore the HBS Gaskets

Unveiling Versatility

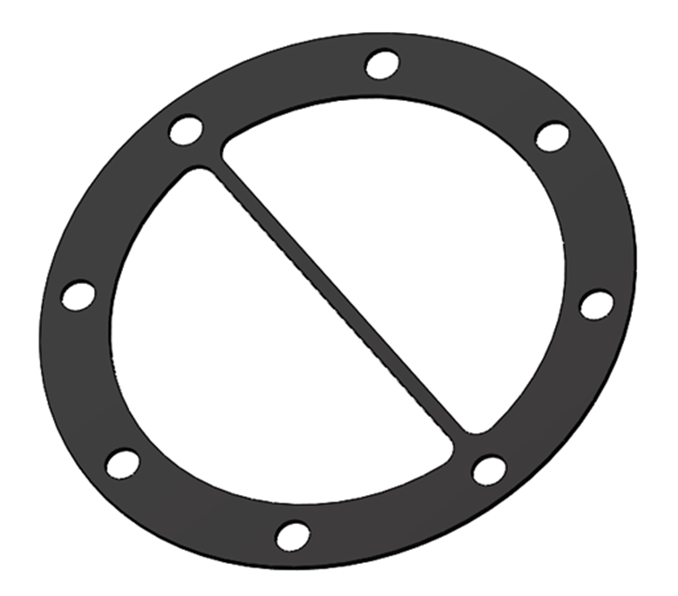

Gaskets span a vast spectrum of shapes, sizes, and materials, meticulously tailored to suit the distinctive demands of each application. From the resilient embrace of rubber to the steadfast fortitude of metal, gaskets proffer a versatile sealing solution for myriad environments, spanning automotive engines, industrial pipelines, and beyond.

Crafted with Precision:

At the core of every gasket lies precision engineering, where meticulous attention to detail ensures a seamless fit and an impermeable seal. Whether molded, cut, or formed, gaskets undergo rigorous manufacturing processes to attain the exacting tolerances and flawlessly smooth surfaces necessary for effective sealing, instilling confidence in even the most demanding scenarios.

A Shield Against Leaks:

Functioning as stalwart guardians against leaks, gaskets staunchly seal joints and connections, staunching the flow of fluids, gases, or contaminants. Their ability to maintain an unwavering seal under fluctuating pressures, temperatures, and environmental conditions renders them indispensable in industries where safety, efficiency, and regulatory compliance reign supreme.

Innovating for Efficiency:

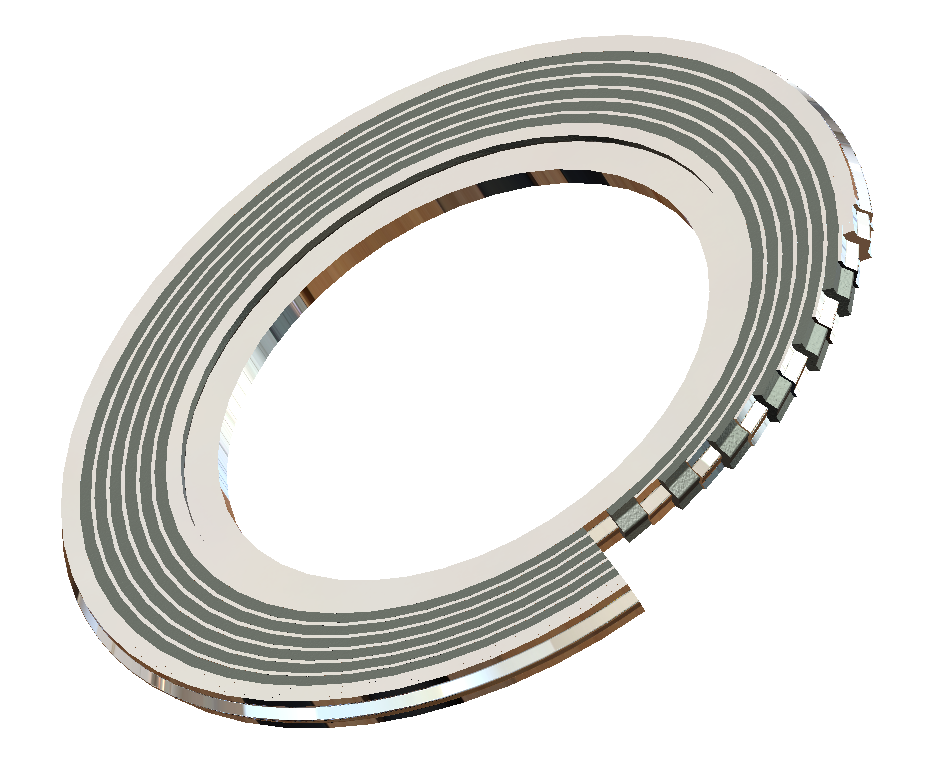

Pioneering advancements in gasket technology continually redefine the boundaries of sealing performance. Innovations such as composite materials, elastomeric coatings, and precision machining techniques augment reliability and longevity, not only enhancing sealing efficacy but also fostering reduced maintenance costs and minimized downtime, thereby bolstering efficiency and productivity.

Where Reliability Prevails:

Visualize gaskets in action—sealing the seams of an aircraft engine slicing through azure skies, or fortifying the integrity of a nuclear reactor core. From the abyssal depths of oceanic exploration to the celestial heights of spacefaring endeavors, gaskets silently discharge their vital duties, preserving equipment, safeguarding environments, and propelling progress across the global landscape.